Checking the condition of the received engine through a comprehensive and detailed engine inspection during disassembly.

Includes inspection of all core-components as well as peripheral equipment.

Right now we have several used engines for sale

Gas engine repair

Refurbish your gas engine — for higher efficiency, less downtime and improving lifetime

PowerUP possesses profound expertise and many years of experience in the repair of gas engines. Whether due to engine damage, gas engine overhaul or gas engine upgrades – PowerUP is the partner you can rely on!

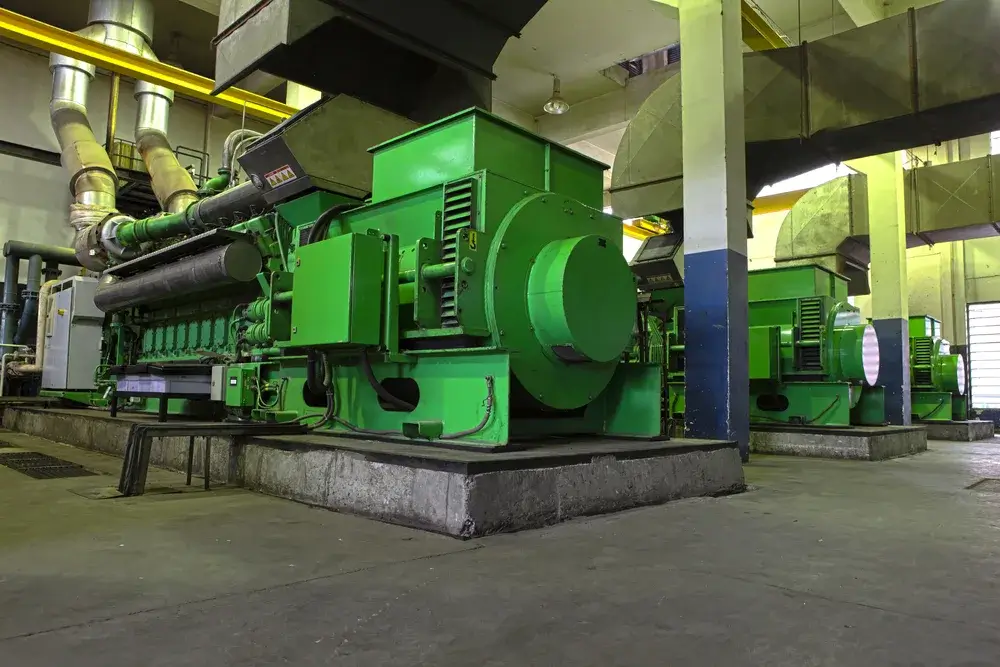

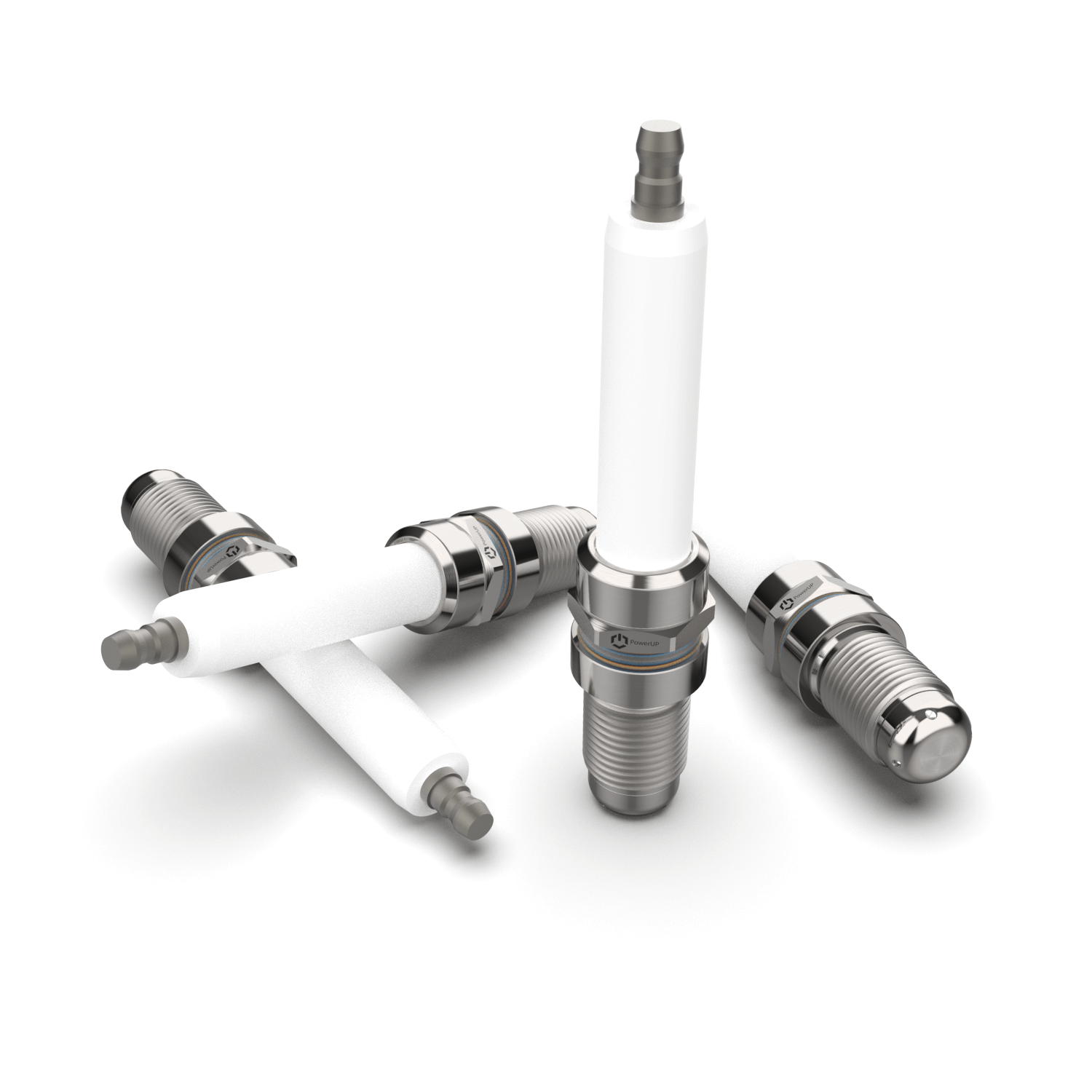

The refurbished engines are equipped with new and often improved gas engine parts as needed. At the same time, the remaining lifespan of the core components is utilized after the gas engine overhaul to offer our customers with gas engines from INNIO Jenbacher®, MWM® and others the best solutions for their needs.

The refurbishment of the unit (gas engine, turbocharger, generator, coolers, and peripheral devices) is carried out using high-quality replacement parts by our qualified engineers and service technicians – in our workshop in Tyrol or directly on-site.

Specializing in Gas Engine Repair for Jenbacher® and MWM® engines, our services cater to the specific needs of these high-quality power units. Our team is equipped with the expertise and specialized tools required to handle the complex systems of e.g. Jenbacher® Type 4 or Type 6 and MWM® TCG 2016 and TCG 2020 engines.

From routine maintenance to complex repairs, we ensure that each engine is meticulously serviced to meet its unique specifications.

Our workflow

Checking the condition of the received engine through a comprehensive and detailed engine inspection during disassembly.

Includes inspection of all core-components as well as peripheral equipment.

During the repair (possibly involving the replacement of parts), the gas engine is thoroughly cleaned.

This step includes the high-pressure cleaning of the crankshafts, the combustion chamber cleaning, as well as the cleaning of cylinder heads and other engine parts.

When assembling the engine, we ensure adherence to precise workflows and the highest responsibility.

During the quality check, a full inspection report detailing the condition of the crucial engine parts is created.

The entire engine is freshly painted in our spray booth in the color desired by the customer.

Afterward, the unit is sent back to the customer, but not before checking for completeness, recording all data, and sealing all openings.

Our specialized gas engine repair services for Shortblocks, Longblocks, and Gensets ensure precision and efficiency in handling engine components.

Our team is equipped to address each type’s specific needs, aiming to restore and enhance their performance for reliable and efficient operation.

Please fill in the form to contact the PowerUP expert team.

We are also happy to answer your questions by phone or e-mail.

Phone: +43 5242 64 666

E-Mail: office@powerup.at