Cylinder Head Optimization: Maximizing Combustion Chamber Reliability for Data Center Gas Engines

It’s the moment every engine mechanic dreads. During a routine borescope inspection, the inspector’s eye falls on the valves and the combustion chamber. Suddenly it’s there: a fine, barely visible line between the valves. A hairline crack.

It may seem insignificant to the layperson, but the expert immediately knows what is at stake. This crack is the precursor to hydrolock. If coolant enters the combustion chamber, it threatens not only the failure of the cylinder but the destruction of the entire unit.

The cylinder head is the Achilles’ heel of any high-performance engine. It must withstand pressures that make steel seem like rubber and temperatures that make metal glow.

Especially in data centers, where motors often remain on standby and then must ramp up to full load within minutes, the stress is extreme. Standard components often reach the end of their service life prematurely.

The solution lies in targeted cylinder head optimization, which increases the material’s durability and thereby ensures the availability of your critical infrastructure.

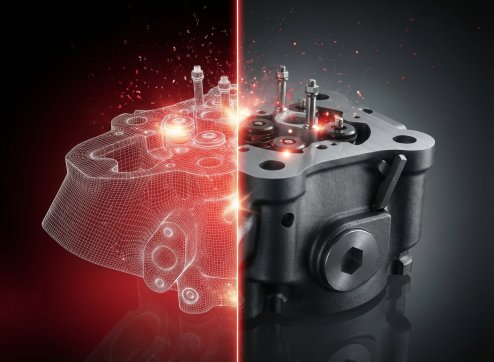

Construction and technical complexity of the cylinder head

The cylinder head is far more than just a cover for the engine block. It is the control centre for combustion and arguably the most complex component in the entire gas engine. Its tasks are manifold, and every single function is critical to operation:

- Sealing of the combustion chamber: It seals the cylinder at the top and must withstand the enormous explosion pressure during every power stroke.

- Gas exchange control: Through the inlet and outlet channels, it precisely regulates the inflow of the fresh gas–air mixture and the outflow of the hot exhaust gases.

- Valve guide: It houses the intake and exhaust valves, which are subjected to high mechanical loads and must open and close thousands of times per minute.

- Cooling: A sophisticated system of water jackets runs through the head to dissipate the enormous heat of combustion, particularly at critical points such as the valve bridges.

- Ignition: Serves as the mounting location for the spark plug or pre‑chamber spark plug and positions the spark precisely at the center of the combustion chamber for optimal flame propagation.

Common causes of defects and material failures

The physical forces acting on a cylinder head are enormous. With each engine cycle, gas pressures of over 200 bar are generated. At the same time, temperatures above 500 degrees Celsius prevail at the exhaust valves, while just a few centimeters away the cooling water flows at 80 degrees Celsius. This enormous temperature difference creates stresses in the material that threaten to tear the metal apart.

The so-called valve bridges are particularly critical. These are the narrow ribs between the intake and exhaust valves. Here, the material is at its thinnest and the thermal stress is highest.

In data center applications, another stress factor comes into play. The “Fast Ramp-Up” forces cold material to expand extremely rapidly. If the design or alloy shows weaknesses, the dreaded stress cracks can develop.

Enhancing resilience through design optimization

To withstand these extreme conditions, simply replacing the standard part with an identical new one is often not enough. The component must be improved beyond the original. Engineers have analyzed these weaknesses and increased robustness through targeted interventions.

The following measures are characteristic of an optimized cylinder head.

- Improved cooling channels: Adjusting the water jacket ensures the coolant reaches hotspots, such as the valve bridges, more quickly and dissipates heat more efficiently.

- Higher-quality alloys: The use of special cast alloys with greater creep resistance prevents the material from undergoing plastic deformation under heat and pressure.

- Reinforced geometry: Critical areas receive additional material to increase mechanical stiffness and minimize vibrations.

These measures deliver maximum combustion-chamber reliability for data center gas engines. The head breathes less under load and withstands thermal cycling for much longer.

Precision in detail: components for specific model series

Each engine series has its own character and places specific demands on the components used. A cylinder head must therefore be precisely matched to the corresponding specification. At PowerUP we offer components that are fully compatible but often feature significant, detailed improvements.

Our spare parts are suitable for use in Jenbacher® (e.g., Series 3, 4, and 6), MWM® (e.g., TCG 2016, 2020, 2032), the Caterpillar® CG series, and other models. They are not original parts from the manufacturers mentioned, but alternatives specifically developed by PowerUP.

We pay particular attention to the movable components in the cylinder head. We use high-quality valve seat rings made from specially formulated hard metals that are designed to resist valve impact and thus prevent compression loss.

Equally important is the use of Rotocaps. These rotating devices impart a slight rotation to the valve with every stroke. They promote self-cleaning of the sealing surfaces and ensure a more uniform thermal load on the components.

Economic benefits of professional refurbishment

A cylinder head with worn guides or valves is not scrap. The massive cast body often has a long service life remaining. The strategy of “reconditioning” or refurbishment is therefore not only more sustainable, but also more cost-effective than constantly buying new ones.

In a professional reconditioning process, the head is first chemically cleaned and subjected to rigorous crack testing. Only if the material is intact are wear parts such as valve guides, seat rings, and springs replaced with new parts of OEM quality or better.

The sealing surfaces are designed to ensure absolute tightness. A rotating exchange program reduces the system’s downtime to just a few hours. The old head is removed and immediately replaced with a head that has already been overhauled.

Preventive measures to avoid operational damage

Even the best cylinder head can be destroyed by improper operating conditions. One of the most common causes of damage is cavitation. If the pressure in the cooling system is too low or the coolant is old, vapor bubbles form that implode and erode material from the casting. Monitoring the coolant quality is therefore essential.

Engine control is equally critical. Engine knock generates pressure spikes that strike the head like hammer blows. Modern knock-control systems must be calibrated to reliably prevent this.

Regular endoscopic inspections, approximately every 2,000 operating hours, serve as an early warning system to detect changes in the valves or incipient cracks before water intrusion occurs.

Technical partnership for your engines’ core components

A robust cylinder head is your safeguard against costly consequential damage. At PowerUP, we understand the forces that act on your engine. That’s why we offer you components that not only fit but also perform.

Trust our expertise in cylinder heads. We offer both optimized new parts and an efficient exchange service for refurbished components.

Among other applications, our products are suitable for use in Jenbacher® and MWM®, as well as other engine brands. They were developed by PowerUP as independent alternatives and are not original parts of the manufacturers mentioned. We help you maintain the long-term mechanical integrity of your combustion chambers.

Invest in technical resilience. Technology is our driving force, and efficiency is our focus.