Right now we have several used engines for sale

Control Systems for Gas Engines

Optimizing engine performance with precision management.

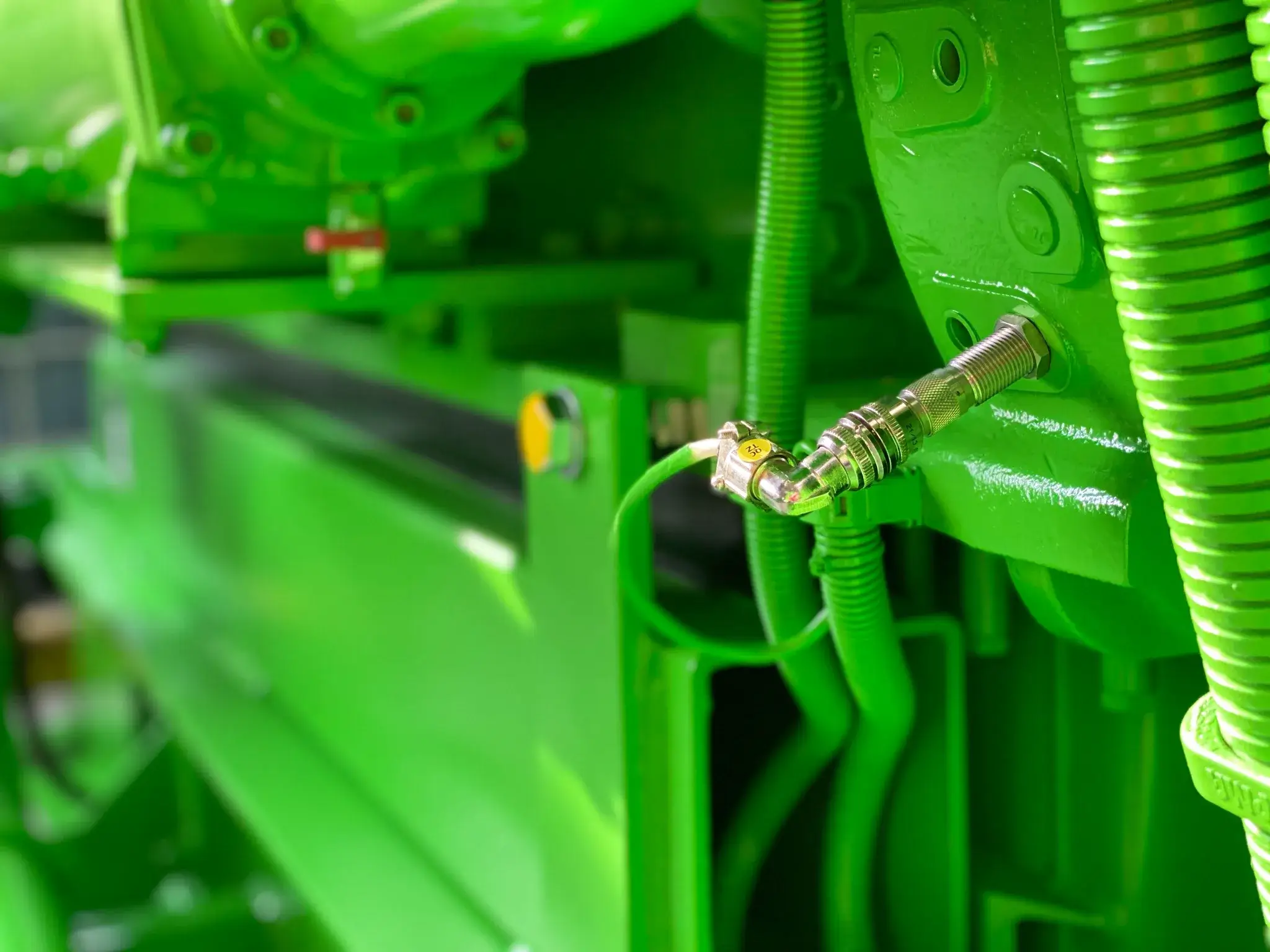

Controller for Jenbacher® and MWM® gas engines

Discover EDI (for Jenbacher®) and AORA (for MWM®), specifically designed to optimize performance and efficiency. These controllers provide advanced management capabilities, ensuring reliable operation and maximizing the lifespan of your gas engines.

Subscribe to the PowerUP Innovation-Letter

Get the the latest innovations and upgrades regarding gas engines delivered to your inbox each month.

Discover the superior performance and innovative design of the Jenbacher®

Type 4 series and learn how this engine series excels in efficiency, durability, and flexibility for diverse power generation needs.

Why does the Jenbacher®

Type 3 series stand out in efficiency, reliability, and versatility for various power generation applications? Dive into the technical details and benefits that make these gas engines a preferred choice for many industries.

This blog post explains what

IPP Energy means, what Independent Power Producers are, their various types, and their significance in promoting sustainable energy solutions.

This blog post takes a closer look at the leading Independent Power Producers (IPPs) from around the world, highlighting their contributions to sustainable energy solutions. Read more!

Jenbacher® engines are renowned for their efficiency in converting fuel into energy. They operate on the principle of internal combustion, where a mixture of air and fuel is ignited to produce power.

Learn how these advanced engines transform fuel into power while maintaining high efficiency and low emissions.

Dive into the world of Jenbacher® engine rebuilds and see how these gas engines get a second life. Learn about the steps involved in restoring an engine to peak performance, from disassembly and inspection to reassembly and testing.

Learn about the distinctive attributes, operational efficiency, and sustainability of each series, from the versatile Type 2 and Type 3 to the powerful Type 9. This guide shows how Jenbacher® engines drive innovation in the power generation sector, setting new standards for performance and environment.

This blog post explores the company's evolution from its modest origins to its status as a global player in providing efficient, sustainable power solutions.

From natural gas to innovative renewable options like biogas and hydrogen, discover the flexibility that makes Jenbacher® engines leaders in sustainable power generation. Let's dive into it!