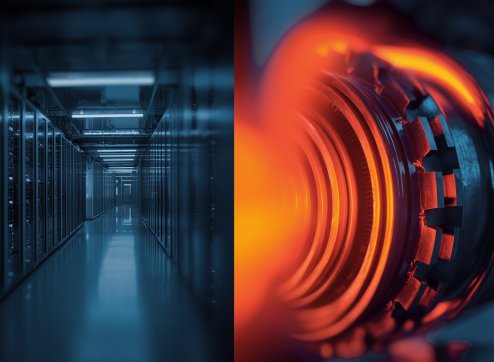

How to prevent overheating and thermal stress in data center operations

As a plant manager, you are responsible for machines that often have to operate at their absolute limits. Your gas engines are high-performance athletes expected to deliver peak performance from a standstill. When the grid falters, every second counts. The “Fast Ramp-Up” is indispensable to the security of the data center, but it is torture for the engine.

The combustion chambers reach temperatures exceeding 2,000 °C. While the cooling water is only at a moderate 40 °C, the valves are already glowing. This enormous thermal stress on the gas engine is one of the most common causes of premature failures.

Overheating is rarely a sudden event; it is a gradual process that destroys the metal’s structure. Those who do not take proactive measures risk costly damage and unplanned downtime.

The goal must be to keep the machine’s head cool, achieved through strategies that minimize thermal stress.

Thermal stress: The invisible killer of materials

It’s not just the absolute temperature that damages the engine. It’s the rapid change and the resulting temperature gradient within the component. If the material in the combustion chamber expands rapidly while the surrounding cast housing remains cold, enormous stresses develop. Metal fatigues under such cyclic loading, like a wire that’s bent repeatedly.

The consequences of this heat buildup are often catastrophic and usually only become apparent when it is too late. Common types of damage include cylinder-head cracks in the bridges between the valves or burnt valve-seat rings that no longer seal. The engine oil also suffers from the heat.

It forms coke deposits on the piston rings, which cause the lubricating film to rupture and, in the worst case, lead to piston seizure. Emergency generators in particular, which frequently have to perform cold starts without sufficient preheating, are especially at risk.

Root Cause Analysis: Why Engines Overheat

When an engine overheats, the cause is rarely just the load itself. Often it is a combination of inadequate maintenance and unfavorable operating conditions. Restricted engine cooling is a common culprit. Dirty charge-air coolers (intercoolers) can no longer adequately cool the intake air, causing combustion temperatures to rise. Clogged external radiators, often blocked by pollen or leaves, also significantly reduce cooling performance.

Another factor is the engine’s tuning. A mixture that is too lean burns hotter and more slowly, which increases the thermal load on the exhaust valves. Equally critical are structural defects in the engine room.

A so-called “thermal short circuit”, in which the hot exhaust air from the tabletop cooler is drawn directly back in, leads to a heat buildup that even the best cooling system cannot compensate for.

Structural Upgrades: Heat-Resistant Hardware

Standard spare parts are often designed for continuous operation under ideal conditions. In the harsh day-to-day reality of data centers, with their load peaks, they sometimes fall short. Here, it’s worth considering engineering upgrades that have been specifically developed for greater thermal resilience.

Optimized components for enhanced stability

Specialist suppliers such as PowerUP rely on components that address the heat issue by design.

- Improved cylinder heads: By optimizing the routing of the coolant channels, heat is dissipated more quickly at critical points, such as the valve bridges, minimizing the risk of stress cracking.

- Heat-resistant materials: Using special alloys in valves and seat rings makes them more resistant to thermal erosion and prevents valve hammering.

- Coated pistons: Special coatings reduce heat from friction and protect the piston crown from direct exposure to the flame front.

Intelligent monitoring: digital hotspot detection

You can’t see heat, but you can measure it. In the digital age, flying blind is no longer an option. Continuous exhaust gas temperature (EGT) monitoring for each individual cylinder is the most important tool for early detection.

Systems such as our in-house development AORA (suitable for use in MWM®) or EDI (with partner AVAT®) make thermal imbalances visible. If a cylinder consistently runs 30 degrees hotter than average, that is a warning sign of a faulty injector or an ignition problem.

These digital guardians detect “hotspots” long before the material gives way. Knock control also provides thermal protection: when knocking combustion begins — which generates massive temperature spikes — it automatically adjusts the ignition timing to protect the engine.

Prevention through care: cleanliness provides cooling

Even the best technology is useless if the foundation isn’t right. Cleanliness is, quite literally, cooling. Regular cleaning of heat exchangers and air filters ensures that thermal contact resistance stays low and that heat can be dissipated efficiently to the environment.

One often underestimated factor is the coolant itself. It not only transports heat but also protects against corrosion. An incorrect pH level or an insufficient glycol concentration can lead to deposits (scale, rust) in the engine block.

These act as an insulating layer and prevent the engine’s cooling system from drawing heat out of the metal. Regular analyses of the coolant are therefore just as important as oil analysis.

Keep a cool head — with PowerUP

Heat is unavoidable, but it can be managed. At PowerUP, we help keep your motors thermally stable even during demanding operating conditions. We understand the physics of overheating and offer technical solutions to minimize risks.

With components designed for high thermal loads and modern diagnostic tools, we help you monitor temperatures. Our solutions are suitable for use in Jenbacher®, MAN®, MWM® and other makes. These components are not original parts from the manufacturers mentioned, but specially developed alternatives from PowerUP.

Whether through optimized cylinder heads or precise controls, we help you reduce thermal stress and extend the life of your investment. Technology drives us; efficiency is our focus.