Blowby filters in gas engines – function, benefits, and efficiency potential

Imagine running a marathon at full sprint, non-stop, for weeks on end. That is essentially what your gas engine does. It is a high-performance athlete, designed for endurance and efficiency. But even the strongest athlete has an invisible enemy. In the case of your gas engine, this enemy comes from within. It creeps past the piston rings, creates unwanted pressure, and carries a toxic mix of oil and soot that can silently suffocate your engine’s performance.

We are talking about blow-by. While often treated as a minor nuisance, effective management of these gases is the thin line between a clean, efficient engine and one plagued by downtime and expensive repairs.

In this article, we look beneath the valve cover to understand the critical role of the blowby filter, explore why standard solutions often fall short, and show you how optimizing this single component can protect your investment and improve your operational reliability.

The invisible enemy within your engine

To understand the solution, we must first understand the problem. During the combustion process, high pressure builds up in the combustion chamber. Ideally, all this pressure would push the piston down. However, no seal is perfect. A small fraction of the combustion gas forces its way past the piston rings and into the crankcase. These escaping gases are known as blow-by gases.

This creates a dangerous situation. If these gases are trapped, crankcase pressure rises. This pressure needs to go somewhere. Without a way to escape, it would eventually blow out a gasket, cause oil leaks, or even damage internal engine components.

But pressure isn’t the only issue. These gases are dirty. They are a hot mixture of unburned fuel, exhaust fumes, and vaporized engine oil. If this mixture isn’t managed correctly, it becomes a major contaminant that threatens the longevity of your engine.

What is a blowby filter?

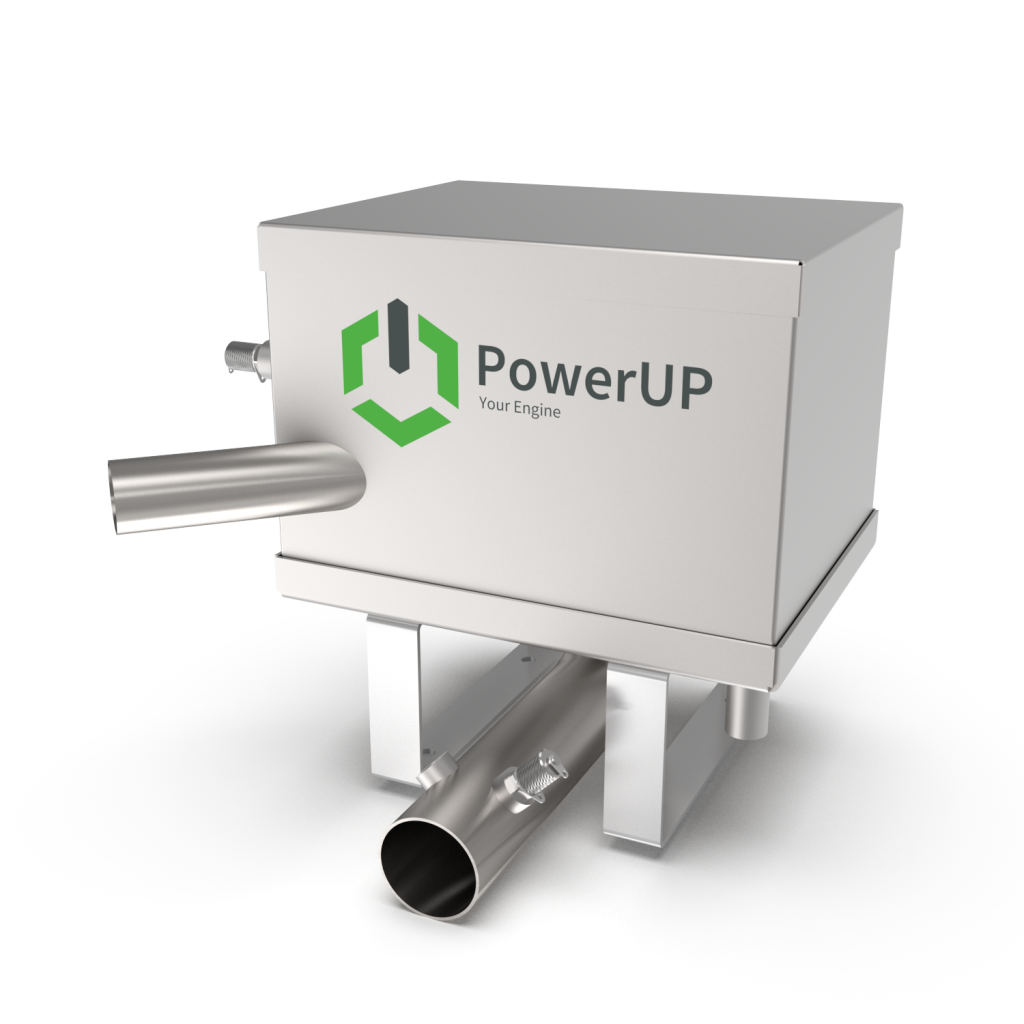

A blowby filter (often called an oil separator or crankcase breather filter) is the core component designed to tackle this mixture. Its function is straightforward but vital: it separates the oil from the gas before reintroducing each into the engine system.

- The Oil: The captured oil is drained back into the oil pan (sump) to be reused, preventing waste.

- The Gas: The cleaned gas is routed to the intake manifold to be burned in the combustion process.

In larger industrial engines, solid filtration has become the preferred method over simple baffle systems due to its reliability and cost-efficiency. By effectively filtering out the oil mist, the component ensures that only clean gas enters the intake, protecting the engine from within.

Why standard filtration often fails against oil mist

The theory sounds simple: separate the oil, vent the gas. In practice, however, standard filtration solutions often struggle to keep up with the demands of continuous operation.

If the blowby filter becomes saturated or isn’t efficient enough, it allows oil mist and other contaminants to pass through. In a closed system, this oily residue is sent straight into your air intake.

The consequences are a domino effect of inefficiency:

- Buildup on Turbochargers: The oil mist coats the compressor blades of turbochargers, reducing their efficiency and lifespan.

- Clogged Intercoolers: Oil mixes with dust and creates a sludge that blocks heat exchangers.

- Reduced Engine Performance: As the engine effectively chokes on its own fumes, efficiency drops, and fuel consumption rises.

- Increased Oil Consumption: Oil that is not separated is burned off, meaning you have to top up the engine oil more frequently.

- Emissions Issues: Burning oil creates heavy soot and negatively impacts your emissions profile.

For the operator, this translates to frequent maintenance stops to clean components and the constant worry that a cheap filter is causing expensive damage.

The difference between industrial and automotive requirements

It is important to draw a clear distinction here. When people hear terms like “high performance” or “performance parts”, they might think of the automotive world. A mechanic might be servicing a Ford pickup truck, installing APR tuning software, or tightening upgraded studs on a sports car engine. They are dealing with small fuel filters and a standard fuel tank.

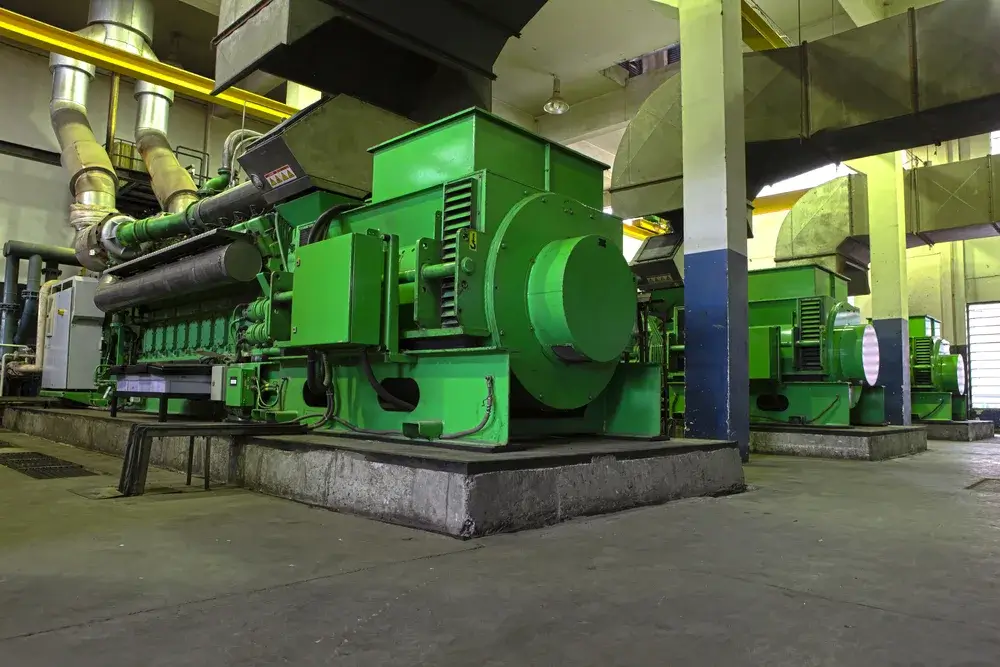

However, industrial gas engines—like those from Jenbacher® or MWM®—play in a different league. While an automotive engine might run for a few hours a day at varying loads, a gas engine in a biogas plant or IPP facility runs 24/7 at constant high load.

An automotive pick up filter is designed for intermittent use. Industrial blow-by solutions must handle massive volumes of gas and continuous oil separation for thousands of hours without clogging. Using “standard” or automotive-grade logic for industrial applications is a recipe for disaster. You need specialized, heavy-duty solutions suitable for the specific demands of power generation.

Deep filtration technology for extended intervals

To combat saturation and maintain efficiency over thousands of operating hours, advanced technology is required that goes beyond standard OEM specifications. This is where deep filtration comes into play. Unlike surface filters that clog quickly, multi-layered filter media capture oil mist deep within their structure.

This specific design allows for significantly extended service intervals, ensuring that maintenance schedules are dictated by your operations, not by a clogged filter. By achieving separation efficiency of up to 99.9%, this technology protects critical components like turbochargers and prevents buildup in the intercooler. Furthermore, high-quality alternatives often come with warranty terms that provide peace of mind, proving that high performance and reliability can go hand in hand without compromising operational security.

Case Study: Major efficiency gains through blowby filter upgrade

Standard OEM blowby filters often rely on one or two filtration stages. Over time, the filter medium becomes saturated, leading to rising differential pressure and eventually requiring replacement – often after just a few thousand operating hours.

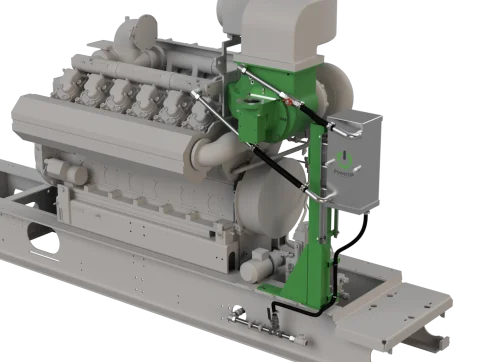

PowerUP took a different approach by developing a patented deep filtration technology. The system uses a multi-layered filter fabric with integrated drainage channels, delivering:

- A high separation rate of 99.98%

- Less than 1 mg/m³ of residual oil

- Stable pressure levels over tens of thousands of hours

Thanks to this innovative design, filter lifespan exceeds 40,000 operating hours. This translates into fewer maintenance stops, reduced downtime, and significant cost savings – especially in high-load engine environments.

One of PowerUP’s customers faced persistent issues with clogged OEM blowby filters, which caused maintenance delays and increased the risk of overpressure in the crankcase. Filters had to be replaced every 4,000–8,000 hours depending on the setup.

By switching to the PowerUP blowby filter solution, the customer achieved:

- Extended filter life beyond 40,000 hours

- Consistently low differential pressure

- More than 60% reduction in maintenance costs

- Seamless compatibility with Jenbacher® and MWM® engine systems

Today, over 500 units and retrofit kits are in operation worldwide, delivering reliable performance across a wide range of applications and gas types.

Want the full breakdown of the implementation, technical performance, and results?

Comprehensive engine care and the ecosystem

A blowby filter never works in isolation. It is part of a delicate ecosystem. If the air filter fails, dust enters the engine and mixes with oil, creating a sludge that overworks the blowby separator. Similarly, if oil filters are neglected, dirty oil returns to the sump, stressing the entire lubrication circuit.

Even the valve cover gasket relies on the ventilation system functioning correctly to avoid being blown out by excess pressure. Neglecting one part, like the crankcase breather filter, puts stress on everything else.

Optimize your engine’s potential

Technology is our drive, efficiency is our focus. Whether you are running a biogas plant or managing an IPP fleet, you cannot afford to let invisible blow-by gases eat into your profits. PowerUP offers solutions suitable for Jenbacher®, MWM®, and other manufacturers that utilize this advanced deep filtration technology to extend component life and reduce your total cost of ownership.

Contact us today to upgrade your filtration system and experience the difference expert engineering makes.