Challenges of Gas engines: An overview of technology and applications

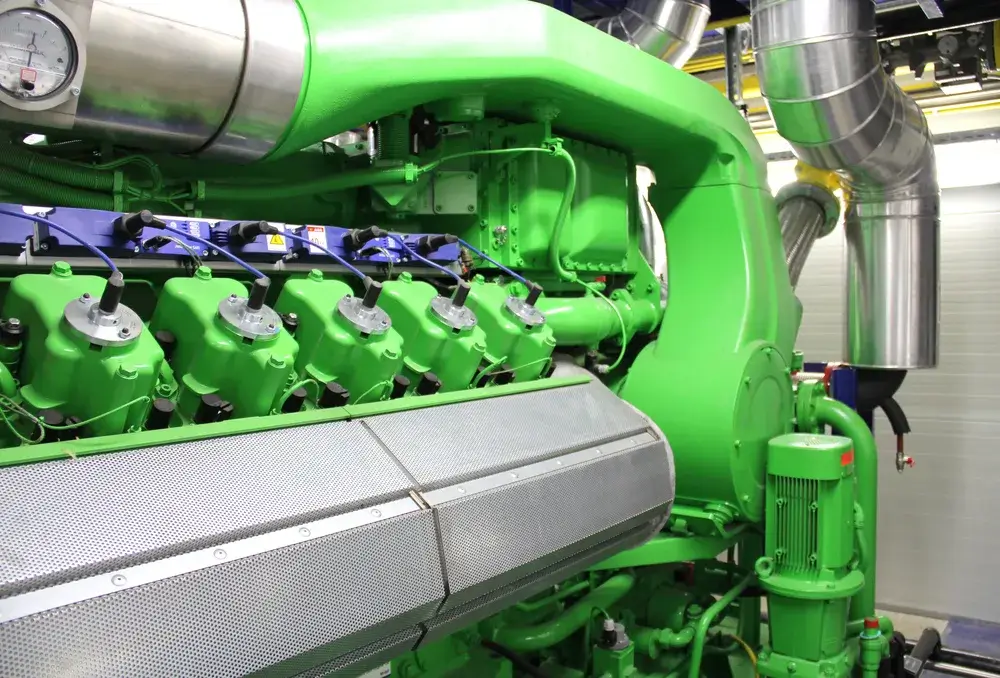

Gas engines are a cornerstone of modern, decentralized power generation. When operating correctly, these internal combustion engines offer unmatched engine efficiency and reliability. However, achieving and maintaining this high engine performance is not automatic.

Operators of heavy-duty systems, from biogas plants to natural gas engine fleets, face significant technical, environmental, and economic hurdles. These gas engine challenges can impact everything from fuel consumption and emissions to operational uptime.

This article is a deep dive into the specific problems that define engine operation and explores the advanced gas engine technology required to overcome them and truly optimize your assets.

The Core Technical Challenge: Fuel Variability and Quality

One of the most significant gas engine challenges stems from the fuel itself. Unlike highly standardized liquid fuels like diesel or gasoline, gaseous energy sources are highly variable. While pipeline natural gas is relatively stable, alternative fuels like biogas, landfill gas, or syngas introduce immense complexity into the engine operation.

This variability in the fuel mixture is a primary technical hurdle for gas engine technology, directly impacting engine performance, reliability, and long-term durability. Fluctuations in chemical composition, energy content, and the presence of contaminants can disrupt the entire combustion process, forcing the engine’s control systems to constantly adapt or risk damage.

Challenges of Gas engines: An overview of technology and applications

A deep dive into the biggest gas engine challenges. Learn about the technical and environmental hurdles, from methane slip and NOx emissions to fuel quality, biogas contaminants, and heavy-duty operation.

Managing Contaminants in Biogas and Alternative Fuels

The challenge of gas engine technology is significantly amplified when using alternative fuels, especially biogas. Unlike pipeline natural gas, these fuels are often “dirty” and saturated with harmful contaminants that can severely damage heavy-duty gas engine components.

These pollutants include:

- Hydrogen Sulfide (H2S): A highly corrosive gas that, when it bypasses the piston rings, can acidify the lubrication oil and lead to systemic wear.

- Siloxanes: The most critical challenge. These silicon-based compounds (found in landfill and municipal waste) are not burned. Instead, the combustion process transforms them into microscopic, abrasive silicon dioxide particles—essentially sand. This abrasive dust embeds itself in the combustion chamber, grinds down critical gas engine components like cylinder heads and engine pistons, and fouls the spark plug.

- Excessive Moisture: High water content in the gas displaces fuel, disrupts the combustion process, and can lead to corrosion in the fuel system.

This continuous abrasive and corrosive action destroys engine efficiency and leads to catastrophic component failure, making advanced fuel gas treatment an absolute necessity for reliable engine operation.

Fluctuating Methane Number and Caloric Value

A further critical challenge, especially for gas engines running on biogas or non-pipeline alternative fuels, is the unstable energy content. The “Methane Number” (MN) is a key metric that functions like the octane rating for gasoline, indicating the fuel’s resistance to knocking or spontaneous ignition under compression.

This number is directly tied to the concentration of methane in the fuel mixture. Unfortunately, in a biogas digester, the methane percentage can fluctuate daily based on feedstock or temperature.

When the Methane Number drops, the fuel becomes unstable. In a heavy-duty engine designed for high compression ratios, this leads to detonation (knocking), an uncontrolled explosion that disrupts the combustion process.

This phenomenon drastically reduces engine efficiency and can cause catastrophic damage to engine pistons and cylinder heads, leading to complex and costly needs for gas engine maintenance parts.

Conversely, if the fuel becomes too inert (too high in CO2), the spark ignition may struggle to ignite the fuel mixture properly, leading to misfires and a severe loss of engine performance. This constant variability is a major gas engine challenge that requires highly sophisticated, real-time control systems to manage.

Handling Compressed Natural Gas (CNG) and LNG

The gas engine challenges are not limited to dirty fuels. Even when using clean natural gas, the logistics of storing and delivering it to the engine present significant technical hurdles.

While pipeline gas is straightforward, applications in natural gas vehicles or in remote locations require the gas to be stored on-site as either Compressed Natural Gas (CNG) or Liquefied Natural Gas (LNG).

A natural gas engine designed for CNG must operate with extremely high-pressure fuel systems, which adds a layer of complexity and cost to the fuel injection and engine technology.

For heavy-duty applications, this requires robust, specialized components. LNG presents an even greater challenge, as it must be stored cryogenically at -162°C (-260°F). This requires a complex onboard “regasification” system to warm the liquid back into a gaseous fuel mixture before it can enter the combustion chamber. Any failure in this specialized fuel injection subsystem – such as a component freezing or a failure to maintain pressure – will immediately stop the engine operation.

In-Depth Engine Technology: Combustion and Performance Hurdles

Beyond fuel quality, the mechanical design of gas engines themselves presents a unique set of gas engine challenges. The core of the engine technology—from the precision of modern fuel injection systems to the combustion process—is fundamentally different from that of diesel engines or gasoline engines.

In these internal combustion engines, operators are pushing for ever-higher engine performance and engine efficiency. This drive for optimization, however, creates immense stress on all mechanical components, demanding a level of engineering and maintenance precision far beyond that of light-duty applications.

Managing the high temperatures and pressures required for an efficient combustion process is a constant technical battle.

Ensuring Stable Spark Ignition and Combustion

A primary gas engine challenge within the combustion process is achieving a consistent and reliable spark ignition. Unlike gasoline engines, which use a relatively stable, atomized liquid fuel mixture, or diesel engines, which use compression, gas engines must ignite a gaseous fuel mixture that can vary in density and quality.

The spark plug must deliver a high-energy spark at the precise microsecond to initiate a stable flame front within the combustion chamber.

If the fuel mixture is too lean (too much air) or too inert (e.g., high CO2 in biogas), the spark may fail to ignite it, resulting in a misfire. This immediately halts power generation for that cycle, lowers overall engine performance, and releases unburnt methane and hydrocarbons into the exhaust.

Conversely, if the system fails to control the ignition timing perfectly, it can lead to pre-ignition or knocking. This delicate balance, which must be maintained across all cylinders in a heavy-duty engine, makes the spark ignition system one of the most critical and challenging gas engine components of modern gas engine technology.

Component Stress in Heavy-Duty Operation

A fundamental gas engine challenge is the immense physical stress placed on components during heavy-duty engine operation. Unlike light-duty automotive engines, industrial gas engines are designed to run for thousands of hours at or near peak load.

This continuous operation generates extreme, sustained high temperature and immense pressure within the combustion chamber. This thermal load is a primary enemy of engine performance and longevity.

Gas engine components like cylinder heads, engine pistons, and exhaust valves, and even the engine block itself, are constantly exposed to this intense heat. This can lead to material fatigue, micro-cracking, and warping, which compromises the integrity of the combustion chamber.

Furthermore, this excessive heat places a severe burden on the lubrication system. The oil degrades faster at high temperature, losing its viscosity and protective properties.

This combination of thermal stress and potential lubrication breakdown accelerates wear on all moving parts, demanding more frequent gas engine maintenance parts. This leads to shorter service intervals and a higher risk of unplanned downtime, which is a critical concern for any power generation facility.

Managing High Compression Ratios

A constant goal in modern turbocharged gas engine technology is to improve thermodynamic engine efficiency. The primary method to achieve this is by increasing the engine’s compression ratios.

This means the fuel mixture is squeezed more tightly within the combustion chamber just before the spark ignition. Higher compression ratios, often achieved through forced induction via turbocharging or, less commonly, supercharging, extract significantly more energy from the same amount of fuel. This is a direct path to better fuel economy and higher engine performance.

However, this creates one of the most significant gas engine challenges. As compression increases, so do the temperature and pressure of the fuel mixture, bringing it dangerously close to its auto-ignition point.

This massively increases the risk of detonation, or “knocking” – an uncontrolled, spontaneous explosion of the fuel rather than a smooth burn. The violent event disrupts the combustion process, creates damaging pressure spikes, and can destroy engine pistons and cylinder heads.

This challenge is especially severe when using alternative fuels with a low or fluctuating methane number (the gas equivalent of an octane rating), forcing a delicate balance between peak engine efficiency and catastrophic failure in any turbocharged system.

Environmental Impact: The Challenge of Emissions Control

Beyond the internal mechanics and engine technology, the most significant gas engine challenges lie in managing their environmental impact. While gas engines, especially those running on natural gas, are often positioned as a cleaner alternative to diesel engines or coal-fired plants, they are still sources of significant emissions.

These pollutants stem from the combustion of fossil fuels and other alternative fuels. The primary concerns are the release of greenhouse gas emissions, particularly carbon dioxide (CO2) and methane, as well as other airborne pollutants that affect air quality.

Meeting increasingly strict global environmental regulations, which often require detailed emissions reporting and citations to prove compliance, is a complex technical hurdle for all power generation assets.

Reducing Nitrogen Oxides (NOx)

A major category of harmful pollutants produced by internal combustion engines is Nitrogen Oxides, collectively known as NOx. These emissions are not a direct byproduct of the fuel itself, but are formed when nitrogen and oxygen in the air react under the high temperature and pressure of the combustion process.

NOx is a primary component of smog and acid rain, making its reduction a top regulatory priority. This presents a difficult thermodynamic challenge for turbocharged gas engine technology: the very conditions that create high engine efficiency (namely, high temperature and a lean fuel ratio) are the exact same conditions that maximize NOx production.

To optimize this, operators must rely on either a skilled gas engine tuner to implement precise engine tuning (lean-burn concepts) or complex, expensive exhaust after-treatment systems, which may require specific additives to function.

The Problem of Methane Slip and Hydrocarbons

One of the most significant greenhouse gas emissions challenges specific to gas engines is “methane slip.” This refers to unburnt methane that “slips” through the combustion process and is released directly into the atmosphere as part of the exhaust pollutants.

That is a critical issue for the environmental impact of gas engine technology because methane is a far more potent greenhouse gas than carbon dioxide – over 25 times more damaging over a 100-year period.

The slip often occurs from incomplete combustion, especially if the fuel mixture is too lean, or when the intake and exhaust valves overlap. These unburnt hydrocarbons not only represent a direct environmental impact but also a loss of engine efficiency, as they are essentially wasted fuel.

Reducing methane slip is therefore a primary goal for gas engine manufacturers and operators, requiring precise control over the combustion process and advanced engine design to minimize these fugitive emissions.

Minimizing CO2 and Other Pollutants

Finally, while methane and NOx are specific technical challenges, the most fundamental of greenhouse gas emissions from gas engines (especially those using fossil fuels like natural gas) is carbon dioxide (CO2). This is an unavoidable product of a complete combustion process. The primary challenge here is not to eliminate it—which is impossible with hydrocarbons—but to minimize it by maximizing engine efficiency and fuel economy. Every drop of fuel not converted into useful energy is wasted, leading to a higher carbon dioxide footprint per kilowatt-hour.

This forces a focus on optimizing every aspect of engine operation, from reducing fuel consumption at idle to ensuring peak engine performance under load. This challenge is further compounded when compared to the environmental impact of renewable energy sources or electric vehicles, which have zero tailpipe emissions. Therefore, gas engine technology must continually improve its fuel economy and thermodynamic efficiency, providing verifiable data and citations of performance, simply to maintain its feasibility and social license to operate in an increasingly carbon-conscious world.

Application and Operational Challenges

Beyond the internal gas engine technology and environmental impact, some of the most critical gas engine challenges arise from the Applications Gas Engines are placed in. The feasibility and profitability of a power generation asset do not just depend on its engine efficiency, but on how it is operated.

Demands of the modern energy grid and the harsh realities of maintenance and logistics create a complex set of operational hurdles that directly impact engine performance and an operator’s bottom line.

Load Fluctuations vs. Continuous Operation

Industrial gas engines face two fundamentally different, yet equally demanding, operational profiles. The first is continuous base-load operation, common in biogas plants, where the engine runs 24/7.

Here, the challenge is sheer endurance. The second, and increasingly common, challenge is peak-load or balancing operation. In this role, the gas engine technology must compensate for the intermittency of renewable energy sources like wind and solar.

This forces the engine to start, stop, and ramp its power output frequently. This cycling operation is a major gas engine challenge as it accelerates thermal stress, impacts fuel consumption, and causes significantly faster wear on components like the spark plug and bearings than steady-state operation.

The High Cost of Engine Downtime

For any power generation asset, the single greatest operational challenge is unplanned downtime. This is the biggest pain point for operators. For an Independent Power Producer or a farmer with a single biogas engine, a stopped engine means an immediate halt to revenue.

The feasibility of the entire plant depends on continuous engine operation. Every minute the engine is offline, it is not just not making money; it is actively losing money. This downtime can be caused by any of the technical challenges mentioned – a component failure, a fuel quality issue, or an emissions system fault – but the economic result is the same. This makes reliability the most important of all metrics.

Sourcing Reliable Parts: OEM vs. High-Quality Alternatives

When downtime does occur, it triggers the next major gas engine challenge: sourcing replacement parts. Operators and service partners are often caught in a difficult position. They can turn to the original engine manufacturer (OEM) for parts, but this can mean high costs and long lead times, extending the costly downtime.

The alternative is to seek non-OEM gas engine maintenance parts, which may be cheaper or faster but carry a significant risk in quality and warranty coverage. Finding a reliable partner who can supply high-quality, durable alternative parts with a solid warranty and, most critically, fast delivery, is a massive logistical and financial challenge.

This choice directly impacts the speed of repair and the long-term reliability of the engine performance.

How PowerUP Helps You Optimize and Overcome These Challenges

Understanding the gas engine challenges related to fuel, emissions, and engine operation is the first step. The second is implementing a robust strategy to optimize your asset and protect its feasibility.

This is where PowerUP transitions from being an observer of gas engine technology to being your active partner. Technology is our drive, efficiency our focus.

We provide tangible solutions that directly address the engine performance hurdles and operational pains that operators of heavy-duty gas engines face every day.

Our solutions are engineered to solve your specific challenges:

- For Fuel and Contaminant Challenges: We provide specialized upgrades and high-durability spare parts (like cylinder heads, engine pistons, and spark plugs) engineered specifically for demanding alternative fuels like biogas. Where OEM parts struggle with corrosive fuels, our components are designed to last.

- For Emissions and Efficiency Hurdles: We offer advanced control system solutions and state-of-the-art tuning from an expert gas engine tuner. These optimize the combustion process in real-time, reducing methane slip, minimizing NOx, and maximizing your overall engine efficiency.

- For Downtime and Operational Pains: We directly solve the critical challenge of downtime. Our global network ensures we deliver high-quality, reliable gas engine maintenance parts faster than many OEM channels. We combine this with expert field service, remote diagnostics, and comprehensive overhauls—all backed by a strong warranty.

We transform your gas engine challenges from a liability into a high-performance, profitable power generation asset.