How does a biogas plant function?

A biogas plant is a powerful tool in the biogas industry, turning organic waste into a valuable renewable energy source. In our comprehensive guide to biogas plants, we explored the “what” listing the key components from the digester to the CHP unit.

This article now focuses on the “how”. We will take a detailed look at the complex biological function that powers the entire system.

The core function of a biogas plant is based on a process called anaerobic digestion. This is the “how” of biogas production. It is a biological process where a diverse team of microorganisms breaks down organic material in an environment completely without oxygen. This all happens inside the main ferment or, or digester. What sounds like a simple process is actually a complex, four-stage biological journey that must be kept in perfect balance.

The Four Phases of the Fermentation Process

The fermentation process inside a digester is not a single step. It is a sophisticated, four-part biological chain where the waste product of one group of microorganisms becomes the food for the next. These four phases all happen at the same time within the substrate. For the biogas system to function, all four must be in harmony.

Phase 1: Hydrolysis (The Breakdown)

The first function is breaking down the raw materials. The organic material fed into the digester, such as crop residues, food waste, or animal manure, consists of large, complex organic molecules like proteins, fats, and carbohydrates.

These molecules are too large for the microorganisms to “eat” directly. A first group of bacteria releases special enzymes that break these long chains apart into smaller, soluble molecules like simple sugars, amino-acids, and fatty acids.

Phase 2: Acidogenesis (The Conversion)

Once the feedstock is broken down, the second phase, or acid-forming phase, begins. A different set of bacteria, the acidogenic microorganisms, consume the simple sugars and amino acids from the hydrolysis phase.

As they consume these, their waste products are volatile fatty acids (like acetic acid, propionic acid, and butyric acid), along with alcohols, carbon dioxide (CO2), and hydrogen (H2).

Phase 3: Acetogenesis (The Preparation)

The third phase, acetogenesis, is a critical preparatory step for the final gas production. In this stage, acetogenic microorganisms consume the volatile fatty acids (except for the acetic acid) produced during acidogenesis.

They convert these acids into acetic acid, more carbon dioxide, and more hydrogen. This phase is essential because it transforms the substrate into the ideal “food” for the final and most important group of microorganisms.

Phase 4: Methanogenesis (The Gas Production)

This is the final and most critical function of a biogas plant. This is where the actual biogas production happens. Specialized microorganisms called methanogens (a form of Archaea) consume the products from the previous phases: acetic acid, carbon dioxide, and hydrogen. Their biological waste product is methane (CH4). The raw biogas that is captured from the digester is this mixture of methane and the carbon dioxide left over from the earlier phases.

Key Factors Controlling the Function of a Biogas Plant

This four-stage process is powerful but also sensitive. For a biogas plant to function efficiently, an operator must manage several key conditions. Failure to balance these factors can lead to a biological collapse of the digester, which is a primary “Biggest Pain” for any operator.

Substrate and Feedstock Quality

The biogas production is directly impacted by the “food” it is given. The type of feedstock, such as energy crops versus slurry, determines the potential gas yield. More importantly, a consistent, stable supply of the same substrate mix is essential for a stable function. Sudden changes in the feedstock can shock the microorganisms.

Temperature Management (Mesophilic vs. Thermophilic)

The microorganisms are highly sensitive to temperature. Most biogas digesters function in a mesophilic range, kept at a constant 37-40 °C, which is stable and robust. Some plants run in a thermophilic range (around 50-55 °C). This process is much faster and kills more pathogens, but the microorganisms are far more sensitive to any changes in temperature or feedstock.

Retention Time and Loading Rate

Retention time is how long the organic matter stays inside the digester. The substrate must remain in the fermenter long enough (e.g., 30–50 days) for all four biological phases to complete. The loading rate is how much new feedstock is added each day. If the loading rate is too high, the process is pushed too fast.

Process Stability: The Importance of the pH Value

This is the most critical balance. If the loading rate is too high, the acid-forming bacteria (Phase 2) work too fast, producing more acids than the methanogens (Phase 4) can consume. This causes the entire digester to become acidic (the pH value drops). This acidic environment is toxic to the methanogens, which die off, stopping the biogas production entirely.

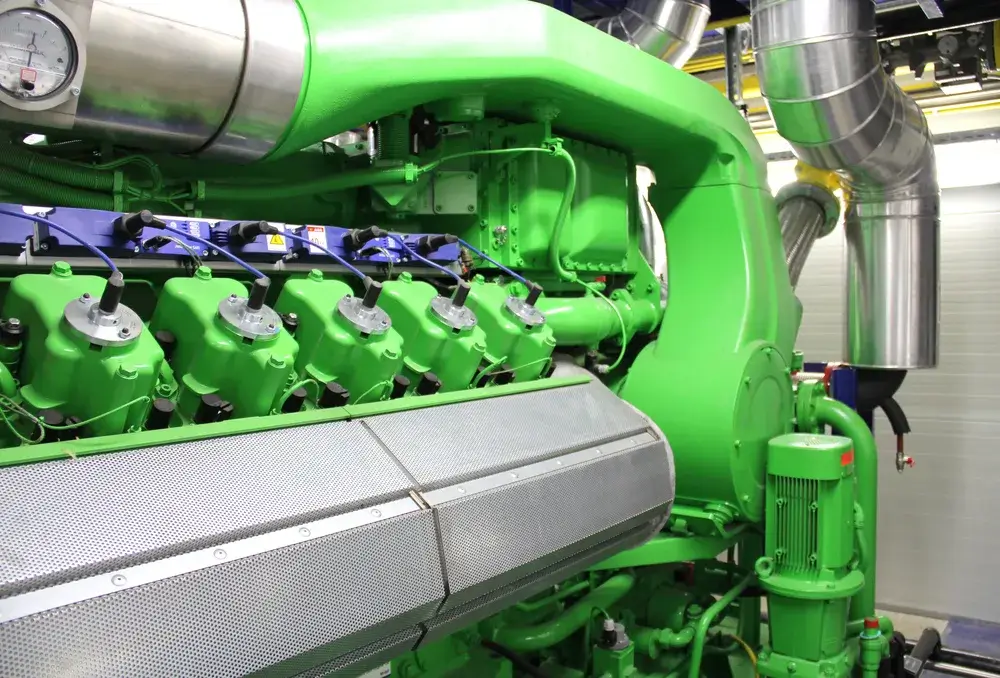

From Biological Function to Mechanical Profitability

Understanding the four phases of methanogenesis is key to managing the biology. But the biological function (methane production) only creates the potential for profit. The mechanical function—the gas engine in the Combined Heat and Power (CHP) unit—is what turns that potential into actual revenue. The reliable function of this engine, which converts the biogas into electricity and heat, is what makes the entire operation profitable.

How PowerUP Ensures Your Plant Functions Efficiently

Technology is our drive, efficiency our focus. The complex biological function of a biogas plant produces a complex and often aggressive biofuel, which can contain sulfur and other contaminants. For your plant to function profitably, your gas engine must withstand these challenges 24/7.

PowerUP is the specialist for ensuring the mechanical function of your plant. We provide robust, high-durability spare parts and expert service suitable for Jenbacher and MWM engines, ensuring your CHP unit runs reliably, resists the harsh biogas, and keeps your entire biogas production process profitable.