Biogas Plants: A Comprehensive Guide to Biogas Production

Biogas plants are a cornerstone of the renewable energy landscape and a vital technology in the biogas industry.

These energy production facilities are a powerful example of sustainable energy, solving two major problems simultaneously: they provide effective waste management by processing organic waste, and they create a reliable, dispatchable source of energy.

Unlike other renewables, a biogas plant can generate bioenergy 24/7, replacing fossil fuels and reducing greenhouse gas emissions. This guide provides a comprehensive overview of the entire biogas system, from its core function to the technology required to optimize its operation.

The Function: How Anaerobic Digestion Powers a Biogas Plant

The core function of a biogas plant is based on a complex, natural biological process. This entire production process is known as anaerobic digestion.

In simple terms, this means that specialized microorganisms break down and consume organic matter in an environment completely without oxygen.

This biological activity, often called the fermentation process, is precisely what generates the biogas. This all takes place in the heart of the facility, a large, sealed tank called the digester.

How does a biogas plant function?

How does a biogas plant function? We explain the 4-phase biological process of anaerobic digestion, from hydrolysis and acidogenesis to methanogenesis, and detail how microorganisms create biogas.

The Main Components of a Biogas System

A modern biogas plant is a sophisticated biogas system where each component is optimized for the production process. While the digester is the heart of the operation, it relies on a series of other essential parts to manage the inputs and outputs effectively.

Feedstock Reception and Pre-treatment

This is the starting point where all raw materials arrive. The feedstock (such as food waste, animal manure, or agricultural waste) is weighed and tested. It is then often shredded, mixed, or pasteurized in a pre-treatment step to prepare the organic material for the fermentation process and to ensure a smooth, homogenous slurry can be fed into the biogas digesters.

The Digester (Fermenter): The Heart of the Plant

The digester (or fermenter) is the central component. It is a large, airtight tank—often several—where the anaerobic digestion actually happens. Inside biogas digesters, the organic matter is heated (typically to 37-40 °C) and slowly stirred, allowing the microorganisms to break down the substrate over a period of 20–60 days. This process is what produces the raw biogas.

The Gas Storage and Upgrading System

As the biogas (a mixture of methane and carbon dioxide) is produced, it is captured at the top of the digester, often under a flexible membrane, which also serves as storage. From here, the gas can either be sent for upgrading (a process to remove the carbon dioxide and impurities to create pure biomethane, also known as renewable natural gas) or sent directly to the CHP unit.

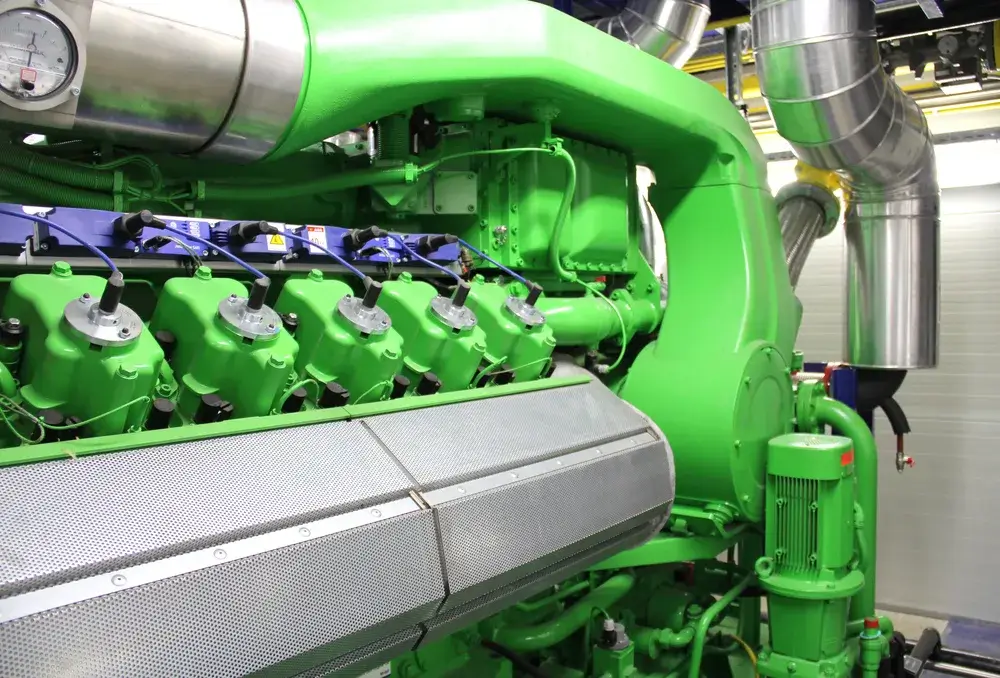

The Combined Heat and Power (CHP) Unit

For most on-site biogas projects, the most crucial component for profitability is the Combined Heat and Power (CHP) unit. This is a specialized gas engine designed to run on raw biogas or landfill gas. This engine turns the biofuel into two valuable outputs: electricity (which is sold to the grid or used on-site) and heat. This bioenergy production is a highly efficient form of energy production.

Digestate Storage (The Byproduct)

After the microorganisms have extracted the energy, the leftover material is called digestate. This is the main byproduct of the biogas system. It is pumped out of the digester and stored in a large tank or lagoon. This digestate is not waste, it is a highly valuable, nutrient-rich, and low-odor liquid fertilizer that can be used on crops.

What is the difference between natural gas and biogas?

What is the difference between biogas and natural gas? This article provides a detailed comparison of their origin, composition (methane vs CO2), calorific value, and environmental impact (fossil fuel vs renewable).

The Feedstock: What Fuels a Biogas Plant?

A biogas plant is only as good as the feedstock it is fed. The choice of raw materials, collectively known as the substrate or biomass, determines the potential biogas production and the stability of the fermentation process.

A key advantage of anaerobic digestion is its flexibility, as biogas digesters can process a vast range of organic material that would otherwise be considered waste.

The most common feedstock used in the biogas industry includes:

- Animal Manure: A primary substrate on farms, including liquid slurry and solid animal manure. Using it in a digester prevents harmful methane emissions that would otherwise be released from open storage.

- Energy Crops: Plants such as corn, grass, and rye that are grown specifically for their high bioenergy content.

- Agricultural Waste: Leftovers from farming, such as straw, husks, or crop residues that remain after harvest.

- Organic Waste: This category includes industrial food waste from processing plants, supermarkets, or municipal organic waste collection programs.

- Sewage Sludge: A common feedstock for municipal biogas plants, which process the sewage sludge (biosolids) from wastewater treatment plants.

The Outputs: Biogas, Biomethane (Renewable Natural Gas), and Digestate

The biogas production process creates three valuable outputs from the initial organic waste. Understanding these outputs is key to seeing the full value of a biogas system.

Raw Biogas for On-site CHP

The primary output is raw biogas, which is roughly 60% methane and 40% carbon dioxide, with small traces of other gases. This biofuel is most commonly used directly on-site in a Combined Heat and Power (CHP) unit.

The CHP engine is specifically designed to burn this raw gas to generate electricity (for the grid) and heat (for the digester and other buildings), maximizing the energy production of the biogas plant.

Biomethane as a Renewable Natural Gas

Alternatively, the raw biogas can go through a process called upgrading. This process scrubs the gas, removing the carbon dioxide, moisture, and other impurities. The result is biomethane, a biofuel that is over 97% pure methane.

This product is also known as Renewable Natural Gas (RNG) and is chemically identical to fossil natural gas. This purified biomethane can be injected directly into the existing natural gas grid, or compressed and used as a clean vehicle fuel (CNG) for trucks and buses.

The Byproduct: Nutrient-Rich Fertilizer

The final output is the digestate, the liquid and solid organic matter left over after the anaerobic digestion process. This byproduct is a high-value, nutrient-rich fertilizer.

It is more stable, less odorous, and its nutrients are more readily available to plants than raw slurry or animal manure. This creates a perfect closed-loop system for farms, turning waste into energy and a superior fertilizer.

Key Advantages of Biogas Production

The biogas production process offers powerful, multi-layered benefits, making it a key technology for both sustainable energy and circular economies. It is a comprehensive solution for waste management and energy production.

Low-Cost, High-Value Byproduct: The process creates digestate, a high-quality, low-cost fertilizer as a byproduct, reducing the need for synthetic chemical fertilizers and improving soil health.

Renewable Energy Source: A biogas plant is a dispatchable renewable energy source. Unlike wind or solar, it can produce energy 24/7, providing reliable baseload power and replacing fossil fuels.

Effective Waste Management: It transforms a wide range of organic waste—including food waste, slurry, and animal manure—from a costly disposal problem into a valuable source of energy.

Reduction of Greenhouse Gas Emissions: A biogas plant fights emissions on two fronts. It captures methane emissions that would naturally be released from decomposing animal manure or landfill gas, and it reduces carbon dioxide by displacing fossil fuels.

How to Optimize Your Biogas Plant for Profitability

While the benefits are clear, the profitability of biogas projects depends on one critical factor: reliability. The production process is complex, but the biggest challenge for any operator is the Combined Heat and Power (CHP) unit. Raw biogas is an aggressive biofuel, it contains hydrogen sulfide, moisture, and siloxanes that can destroy standard engine components. This leads to frequent downtime, which is the biggest pain for operators. A stopped engine means no energy production and no revenue.

This is where PowerUP becomes your essential partner. We are specialists who optimize the efficiency and reliability of biogas projects. Technology is our drive, efficiency our focus.

We understand the challenges of the biogas industry and have engineered a range of high-durability, specialized spare parts suitable for Jenbacher and MWM engines. Our solutions are designed to withstand the aggressive nature of biogas, reduce downtime, and make your biogas system more low-cost to operate. We ensure your biogas plant runs profitably.