Decoding Biogas Plants – The Main Components and Their Significance

Biogas plants have become an integral component of the renewable energy landscape. They not only offer a sustainable method for energy generation, but also contribute to reducing the carbon footprint.

But what actually lies behind these installations and successfully farming biogas? What are the key components that drive them, and how do they contribute to the overall process of energy production? In this blog post, we will concentrate on the main components of a biogas plant and elucidate their significance in detail.

Biogas Plants – A Comprehensive Guide

In this PowerUP article, you will find comprehensive information about biogas plants – from their history and components to their advantages.

The main components of a biogas plant

Biogas plants are complex systems that consist of several critical components to efficiently convert biomass into valuable biogas

These components work together harmoniously to transform organic waste into a sustainable and useful energy source. In the following sections, we will delve deep into the core of this green technology and illuminate the main components of a biogas plant, as well as their respective roles and significance in the overall system.

Substrate processing

Substrate processing is the first and one of the essential phases in the process of biogas production. Before biomass can be used in the fermenter for gas production, it must be properly prepared. In this step, the organic materials, such as plant residues, manure or organic waste, are crushed, mixed, and in some cases, pre-fermented to obtain a homogeneous mass that is more easily degradable for microorganisms.

The proper preparation of the substrate allows for an optimized gas yield and prevents operational issues in subsequent process stages. This process not only removes unwanted components but also breaks down the structure of the biomass, making it easier for microorganisms to access the high-energy molecules. As a result, the entire fermentation process is accelerated and made more efficient.

The fermenter

The fermenter, often referred to as a bioreactor, is the centerpiece of every biogas plant. It is in this closed container that the anaerobic (oxygen-free) fermentation processes occur, during which microorganisms break down the prepared organic materials. This decomposition occurs in multiple stages and ultimately results in the production of methane, the main component of biogas.

The fermenter provides the necessary microorganisms with optimal conditions in terms of temperature, pH value, and nutrient supply to carry out their work efficiently. It is crucial to carefully monitor and control the bioreactor to ensure the continuous and uninterrupted progress of the fermentation process.

After the fermentation process, there are fermentation residues and other by-products of biogas plants left. These residues are abundant in nutrients and contribute to the sustainable improvement of the soil.

Gas storage and treatment

After the biogas has been produced in the fermenter, the next step is gas storage and purification. The raw biogas, which comes directly from the fermenter, contains not only methane, but also other gases such as carbon dioxide, water vapour, and in some cases, hydrogen sulphide.

For many applications, especially when the gas is to be fed into the grid or used as fuel in vehicles, these accompanying substances need to be removed. Therefore, during the purification phase, the gas is cleaned and rid of unwanted components. After purification, the biogas is stored in specialized storage tanks or gas storage facilities.

These storage tanks serve not only for storage, but also for buffering in order to compensate for fluctuations in the production process and ensure a continuous supply of gas.

Heat and power generation

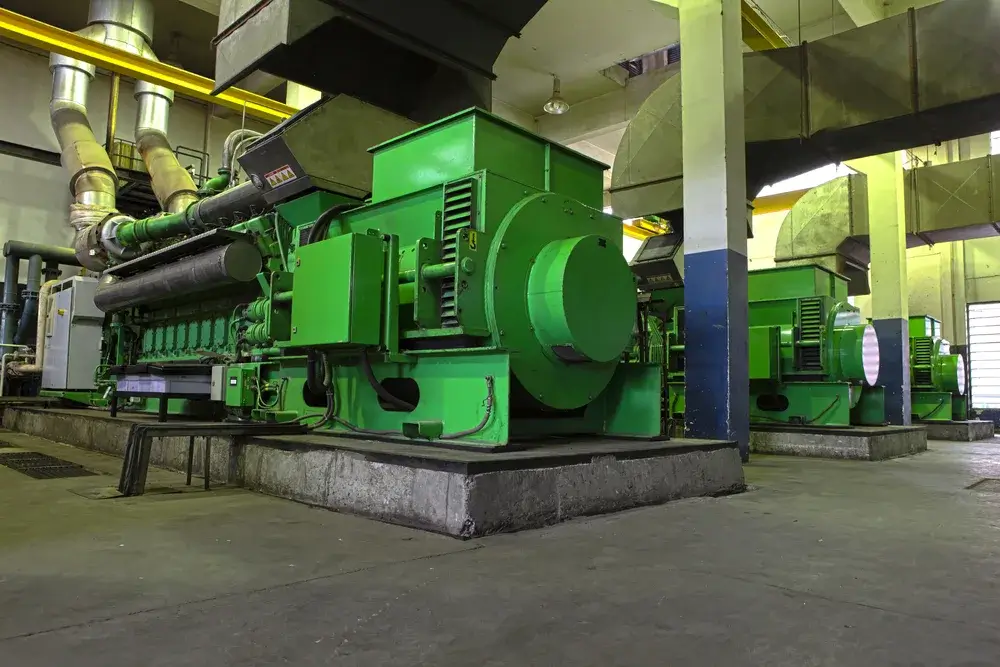

The energy stored in biogas can be utilized in various ways, with heat and electricity generation being among the most common applications

By utilizing combined heat and power (CHP) plants, the processed biogas is combusted to generate both electricity and waste heat – a process referred to as cogeneration. This system maximizes the utilization of biogas energy by efficiently harnessing both thermal and electrical energy.

The electricity generated can be either consumed directly on-site or fed into the public grid. The resulting heat is frequently utilized for heating buildings, in agricultural processes, or to support the fermentation process within the biogas plant itself. This integrated approach to energy generation makes biogas plants an exceptionally efficient and sustainable source of energy.

How does combined heat and power (CHP) work?

Discover how Cogeneration revolutionizes energy by simultaneously generating electricity and heat, cutting CO₂ emissions and enhancing energy efficiency.

The benefits and challenges of biogas plants

The operation of a biogas plant offers numerous advantages that make them a preferred technology in the field of renewable energies. Among their main advantages is their ability to convert organic waste into valuable energy, thereby reducing dependence on fossil fuels and simultaneously reducing waste. Furthermore, they consistently produce energy regardless of weather conditions, which sets them apart from other renewable energy sources like solar or wind energy

However, there are also challenges. The initial investments can be high, and operating a biogas plant requires technical know-how and meticulous monitoring. Additionally, not all organic materials can be efficiently fermented, and gas purification can be complex in certain cases. Nevertheless, despite these challenges, the technology remains an important component in the mix of renewable energies due to its varied ecological and economic benefits.

High-quality components from PowerUP for your biogas plant

Elevate your biogas plant’s performance with high-quality components from PowerUP. Our range of gas engine spare parts ensures your equipment runs smoothly, while our services, including gas engine upgrades and gas engine repairs, keep your operations at peak efficiency. Trust PowerUP to provide reliable solutions tailored to your biogas plant’s needs, enhancing both productivity and sustainability.

Our conclusion

Biogas plants are an impressive example of how innovative technologies can contribute to making our energy supply more sustainable and environmentally friendly. By converting organic waste into valuable sources of energy, they not only offer a solution for waste management but also help to reduce our dependency on fossil fuels.

Despite the challenges in implementation and operation, the long-term benefits outweigh the environmental and economic factors. With advancing technology and increasing awareness of the importance of sustainable energy solutions, it is expected that biogas plants will continue to play a central role in the global energy landscape.