The Ultimate Guide to Jenbacher® Gas Engines

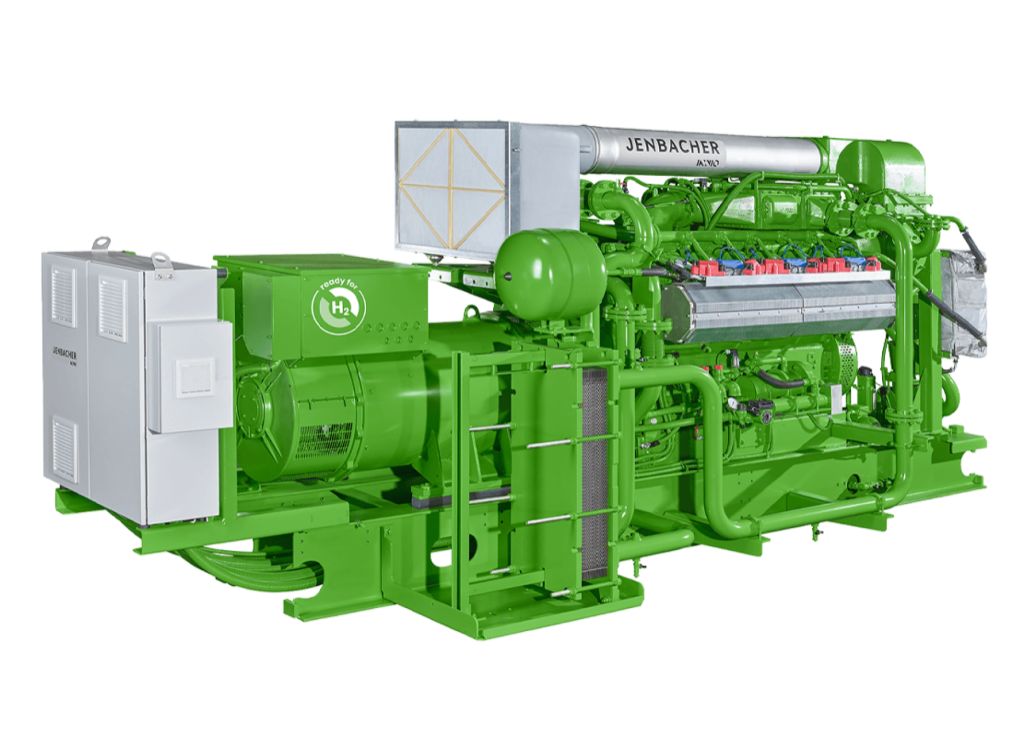

Jenbacher® engines, renowned for their reliability, have carved a niche in the energy sector. They are versatile powerhouses, perfectly suited for a range of applications from biogas projects to large-scale operations and Independent Power Producers (IPPs). Their adaptability and high efficiency make them the ideal choice for anyone looking to implement reliable and sustainable energy solutions across various industries.

In this article we will look into the origin and the future of Jenbacher®, explore the application areas of the gas engines and find out why they are so popular in the world of sustainable power production.

The origin of Jenbacher®

The origin of Jenbacher® traces back to the small town of Jenbach in Tyrol, Austria, where the company began its operations in the 20th century. Initially established in 1959, Jenbacher Werke was primarily focused on the manufacturing of diesel engines. However, over the years, the company diversified its portfolio to include the production of gas engines and generator sets, becoming renowned for its innovative and efficient gas engine technology.

Jenbacher® and GE

A pivotal moment came in 2003, when General Electric (GE) acquired Jenbacher®, marking a significant milestone in its history. This acquisition by GE not only expanded Jenbacher®’s global reach but also infused the company with additional resources to innovate and grow. Under GE’s umbrella, Jenbacher® continued to excel in developing high-efficiency gas engines, further establishing its reputation in the power generation sector.

Jenbacher® and INNIO

The history of Jenbacher® took another significant turn in 2018, when it became a part of INNIO after the latter was formed through the acquisition of GE’s Distributed Power business. This strategic move marked the beginning of a new era for Jenbacher®, allowing it to leverage INNIO’s focus on innovative energy solutions and further expand its presence in the global gas engine market. Under INNIO’s stewardship, Jenbacher® continues to thrive, developing cutting-edge technologies for gas engines that emphasize sustainability, efficiency, and reliability.

The engines are widely used for power generation, particularly in combined heat and power (CHP) applications, reflecting the company’s commitment to sustainable and reliable energy solutions. The Jenbacher® brand has since become a symbol of quality and innovation in the energy sector, with its products serving a global market and contributing significantly to the advancement of environmentally friendly power generation technologies.

The History of INNIO Jenbacher®

This blog post explores the company’s evolution from its modest origins to its status as a global player in providing efficient, sustainable power solutions.

Understanding Jenbacher® Gas Engines

In this section, we’ll uncover the attributes and advanced technologies that define Jenbacher® gas engines, setting them apart in the global market.

What makes INNIO Jenbacher® unique?

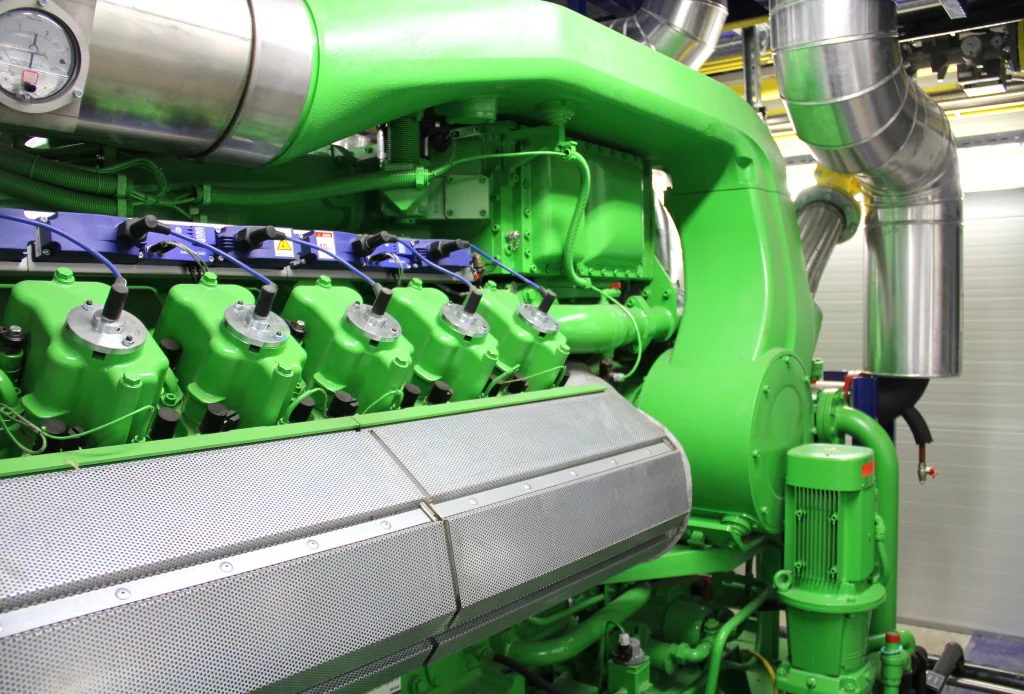

INNIO Jenbacher® gas engines stand out due to their advanced combustion technology, fuel flexibility, and high efficiency (electrical output). They are designed to operate with a range of gas types, from natural gas to biogas, coal gas, landfill gas and many others, making them versatile for diverse applications.

Their robust construction ensures durability and reliability, even under challenging conditions. These engines also boast exceptional environmental performance, with lower emissions compared to some other engines.

Environmental Impact

Jenbacher® gas engines contribute positively to environmental sustainability. Their high-efficiency operation results in lower emissions, notably reduced CO2, NOx, and particulate matter, compared to traditional fossil fuel-based engines.

By efficiently utilizing renewable gases like biogas and natural gas, they support the transition to cleaner energy sources. Additionally, their cogeneration capability maximizes energy use, reducing waste and overall environmental footprint.

Types of Jenbacher® Gas Engines

Jenbacher® gas engines are a leading choice in distributed power generation, known for their efficiency, reliability, and fuel versatility. These engines cater to a wide array of applications across various industries, running on natural gas, biogas, and hydrogen.

This brief overview will delve into the different Jenbacher types, highlighting their suitability for diverse energy needs.

- Type 2 (249 – 330 kW)

The Type 2 gas engine represents an efficient, compact solution for smaller-scale power generation needs. Characterized by its robustness and reliability, the series is designed to operate with a variety of gas types, making it a versatile option for applications ranging from natural gas to biogas and landfill gas. Its compact size and high efficiency make it particularly well-suited for small industrial plants, local heating networks, and agricultural biogas operations.

- Type 3 (393 – 1065 kW)

Recognized for its compact design, the Type 3 from Jenbacher® is perfectly suited for small to medium-sized applications. It combines efficiency with a manageable size, making it an excellent choice for facilities with limited space but requiring reliable power generation. Its versatility and lower emissions profile make it a popular option for urban power plants and industrial operations looking for sustainable solutions.

- Type 4 (749 – 1.562 kW)

The Type 4 gas engines by Jenbacher® step up in terms of power output, catering to more robust industrial needs. With enhanced operational flexibility and efficiency, these engines are designed for medium to large applications, including manufacturing plants, large commercial buildings, and utility power generation. Their reliability and extended service intervals make them a cost-effective choice for continuous operation environments.

- Type 6 (1.818 – 4.507 kW)

For demanding energy requirements, the Jenbacher® Type 6 series stands out with the highest power output among the range. Equipped with advanced technological features, these engines are tailored for large-scale operations, offering unmatched efficiency and performance. Ideal for heavy industrial use and large-scale power generation projects, the Type 6 series exemplifies cutting-edge engineering for maximum productivity and environmental compliance.

- Type 9 (10.606 kW)

The Type 9 gas engine stands for large-scale, high-efficiency power generation. This series is engineered to meet the demands of the most challenging energy projects, offering unparalleled efficiency, reliability, and flexibility in fuel compatibility. The Type 9 series excels in applications requiring substantial power output, such as utility power generation, large industrial complexes, and Independent Power Producers (IPPs). Its cutting-edge design features advanced technologies that optimize performance and reduce emissions, solidifying the Type 9’s position as a leader in sustainable, high-performance power solutions.

This portfolio allows Jenbacher® to effectively meet the wide-ranging energy needs of various industries, from localized cogeneration projects to extensive power generation facilities, ensuring that every customer finds the perfect match for their specific operational demands.

Powering Progress – Our Guide to Jenbacher® Gas Engine Series

Learn about the distinctive attributes, operational efficiency, and sustainability of each series, from the versatile Type 2 and Type 3 to the powerful Type 9. This guide shows how Jenbacher® engines drive innovation in the power generation sector, setting new standards for performance and environment.

Applications of Jenbacher® Gas Engines

Jenbacher® gas engines are deployed across a wide array of applications, demonstrating their adaptability to various energy needs. From generating onsite power in remote locations to supporting the renewable energy sector, these engines are integral to modern energy solutions.

Cogeneration/Combined Heat and Power (CHP)

A primary application of Jenbacher® engines is in cogeneration systems, where they excel at producing both electricity and heat simultaneously. This highly efficient process is used in industries, hospitals, and residential areas, significantly reducing energy costs and carbon footprints.

Renewable Energy Integration

Jenbacher® engines play a crucial role in the renewable energy sector, particularly in biogas and natural gas projects. They convert organic waste from agriculture, landfills, and wastewater treatment plants into valuable electricity and heat, supporting sustainable energy goals and reducing reliance on fossil fuels.

Emergency Power Supply

In areas prone to power outages or lacking grid stability, Jenbacher® gas engines provide a reliable emergency power supply. They ensure continuous operations for critical facilities like hospitals, data centers, and emergency services, where power interruptions cannot be afforded.

MyPlant – Remote Monitoring from INNIO®

The MyPlant monitoring system from INNIO® represents a leap forward in digital engine management and optimization. Designed to enhance the operational efficiency and reliability of gas engines, MyPlant uses AI and leverages advanced data analytics and IoT technology to provide real-time insights into engine performance and health. This cloud-based platform allows users to remotely monitor their engines, receiving instant alerts on potential issues and performance metrics. By facilitating proactive maintenance and enabling precise adjustments, MyPlant helps to minimize downtime and optimize fuel consumption, leading to improved overall efficiency and reduced operational costs.

The Future of Jenbacher® Gas Engines

The future of Jenbacher® gas engines is poised at the cutting edge of innovation, with a clear focus on elevating efficiency and embracing sustainability. The exploration into alternative fuels such as syngas and green hydrogen marks a significant step towards reducing the environmental impact of power generation. These engines are being designed to not only meet but exceed current performance standards while significantly lowering emissions, making them a cornerstone in the transition towards a more sustainable energy future.

In this development towards innovation and sustainability, PowerUP plays a big role by offering comprehensive support and services for gas engines compatible with Jenbacher® models. As a trusted partner, PowerUP is dedicated to ensuring that these advanced engines achieve their full potential, providing gas engine repair and upgrade services. Specially designed gas engine spare parts are one of our main focuses to help our customers to get the most out of their biogas or natural gas engine.

The collaboration between Jenbacher® and PowerUP underscores a shared vision for a greener future, where innovative engine solutions and expert services converge to meet the demands of sustainable power generation. Together, we are setting a new standard for the industry, demonstrating that increased efficiency and sustainability are not just goals but achievable realities with Jenbacher® gas engines.

FAQs for Jenbacher® gas engines

What are the primary applications of Jenbacher® gas engines?

Jenbacher® gas engines are primarily used in industrial power generation, cogeneration systems, and for running on renewable energies like biogas, landfill gas, sewage gas or other special gases. They are well-suited for applications in manufacturing, agriculture, and energy sectors, providing efficient and reliable energy solutions.

Who owns Waukesha Engines?

Waukesha Engines is owned by INNIO, following its acquisition from General Electric’s Distributed Power segment by Advent International in 2018. INNIO now operates both Jenbacher® and Waukesha gas engine brands.

What is the largest Jenbacher machine?

The largest Jenbacher machine is the J920 FleXtra gas engine. It is designed for high efficiency and flexibility, offering one of the highest electrical efficiencies in its class, suitable for large-scale power generation projects.

What are the unique technological features of Jenbacher® gas engines?

Jenbacher® gas engines are distinguished by their advanced combustion technology, ability to operate on a wide range of gas types, and high efficiency. Their robust design ensures reliable performance under various operational conditions, making them a versatile choice for different energy needs.

How often should Jenbacher® gas engines be serviced for optimal performance?

Regular maintenance and overhauls are crucial for the optimal performance and life cycle of Jenbacher® gas engines. The frequency of servicing depends on the engine’s usage and operational conditions. Adhering to the manufacturer’s maintenance schedule and guidelines is recommended to ensure longevity and efficiency.

How often should spare parts like spark plugs be replaced in Jenbacher® engines?

The maintenance schedule for Jenbacher® engines depends on several factors, including the engine model, operating conditions, and fuel type. Typically, Jenbacher® recommends regular inspections and service to ensure optimal performance and longevity of the engine. We from PowerUP e.g. offer a condition based overhaul for gas engines, ensuring the engine operates at its best, with as little economic impact as possible.

How does Jenbacher® contribute to the energy transition with its technology?

Jenbacher® is at the forefront of the energy transition by developing innovative technology that enables the efficient use of renewable and low-carbon fuels, such as biogas, natural gas or even pipeline gas and mine gas.

Through advanced combustion techniques and engine optimization, Jenbacher® gas engines support the shift towards sustainable energy sources by reducing emissions and increasing energy efficiency. Therefore, Jenbacher® engines come into use in various fields, from cogeneration plants to renewable energy projects, showcasing their contribution to a cleaner energy future.

What is the price for a Jenbacher gas engine?

The price of a Jenbacher gas engine varies widely depending on the model, specifications, and configuration. Costs can range significantly, reflecting the engine’s size, power output, and any customized features or technologies included. For accurate pricing and further information, it’s recommended to contact a sales representative from INNIO or an authorized distributor like PowerUP.