By-products of biogas plants and their applications

A biogas plant is rarely just an energy production facility. For many successful operators, the real value lies in the circular economy it creates. The anaerobic digestion process does not just produce biogas, it also creates several valuable by-products.

This article provides a comprehensive guide to the by-products of biogas plants and their applications. We explore the valuable materials produced during the process and how they transform a simple energy plant into a powerful engine for a sustainable, circular economy.

The Primary By-product: Digestate (Fermentation Residues)

The most significant by-product of a biogas plant, in terms of volume and value, is digestate. This is the nutrient-rich material that remains in the fermenter after the anaerobic digestion process is complete. It is crucial to understand that digestate is not waste, it is an upgraded, high-value product.

Liquid Digestate vs Solid Digestate (The Separation Process)

In most large-scale biogas operations, the raw digestate (which is mostly liquid) is processed through a mechanical separator. This creates two distinct and valuable products:

- Liquid Digestate: This fraction contains most of the soluble nutrients, particularly nitrogen and potassium. It is an excellent, fast-acting liquid fertilizer that can be spread on fields to provide crops with readily available nutrition.

- Solid Digestate: This fraction is rich in organic matter, phosphorus, and other micronutrients. It acts as a powerful soil conditioner, helping to build humus and improve soil structure over the long term. In some operations, it is also dried and used as sterile, comfortable animal bedding.

Applications for Digestate as a High-Quality Fertilizer

For many agricultural biogas plants, digestate is the key to profitability. It is a far superior product to the raw manure that was originally fed into the fermenter.

- Nutrient Availability: The anaerobic digestion process converts organic nitrogen into readily available ammonium, a form that plants can absorb immediately.

- Reduced Odor: One of the biggest benefits is the significant reduction in odor. The fermentation process breaks down the volatile fatty acids that are responsible for the harsh smell of raw manure.

- Pathogen Reduction: The time spent in the fermenter, especially in a thermophilic operation, destroys a vast majority of pathogens (like E. coli) and weed seeds, making the fertilizer safer and more effective.

- Replacing Chemical Fertilizers: This is the greatest economic benefit for many operators. They can drastically reduce or even eliminate the purchase of expensive synthetic chemical fertilizers, saving enormous costs and closing the nutrient loop on their own farm.

Secondary By-products: Recovered Heat and CO2

Beyond the digestate, a biogas plant produces two other valuable by-products that are often overlooked.

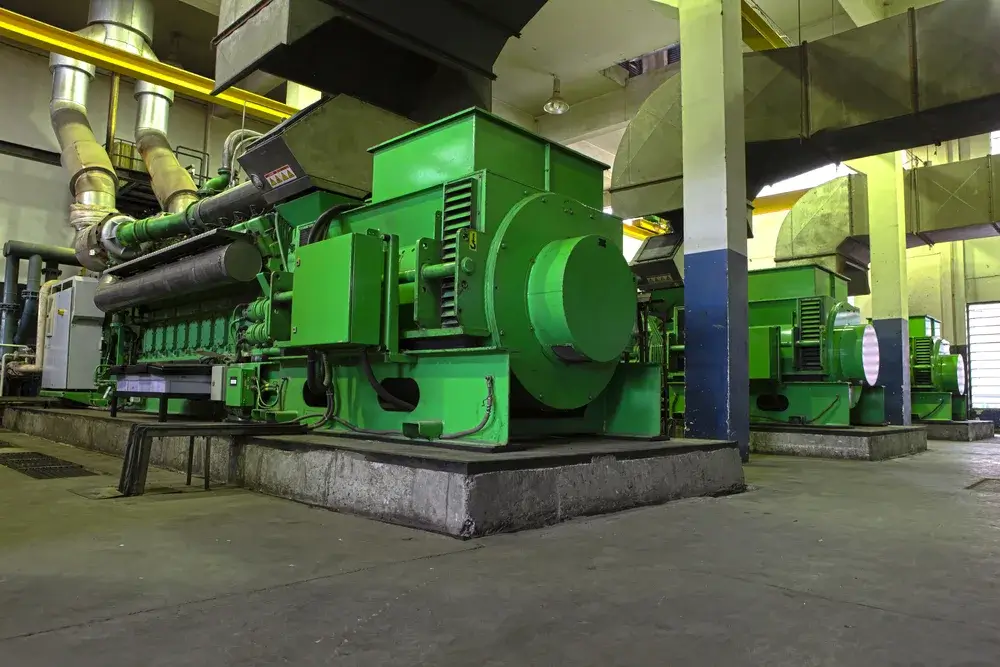

Application: Usable Heat from the CHP Engine

The gas engine, or Combined Heat and Power (CHP) unit, is the heart of the plant’s energy generation. As a by-product of producing electricity, it also generates a massive amount of high-temperature heat from its exhaust and cooling circuits. A portion of this heat is essential for the plant itself, it is used to keep the fermenter at its optimal operating temperature.

The excess heat, however, is a valuable by-product. This thermal energy can be sold or used for:

- Heating agricultural buildings, farmhouses, or entire local community heating networks.

- Industrial drying processes, such as drying grain, wood pellets, or even the solid digestate to make it easier to transport.

Application: Captured Carbon Dioxide (CO2)

This by-product becomes available in a specific type of biogas operation: one that upgrades its biogas to biomethane. During the upgrading process, the raw biogas (methane and CO2) is “cleaned” by removing the carbon dioxide.

This captured CO2 is not a waste product. It is a pure, often food-grade, stream of CO2 that can be liquefied and sold. Its applications include:

- Carbon-doping in greenhouses to accelerate plant growth.

- The food and beverage industry (for example, in carbonating drinks).

How PowerUP Secures the Value of Your By-products

The quality and consistency of all your by-products depend directly on a stable, uninterrupted operation of your biogas plant.

Your digestate is only a high-quality fertilizer if the biology in the fermenter is healthy. The biology is only healthy if the temperature (maintained by the CHP engine’s heat) is constant. Your heat by-product only exists if the CHP engine is running.

This reveals a critical link: the reliability of your gas engine is the key to unlocking the value of your by-products. If your CHP engine fails, the fermenter cools, the biology stalls, your digestate quality drops, and your heat supply disappears.

Technology is our drive, efficiency our focus. PowerUP secures the reliability of the most critical component in this circular economy: the gas engine.

With our robust, high-performance spare parts and expert service for Jenbacher and MWM engines, we ensure your CHP engine runs. We make sure your fermenter stays hot, your biology stays stable, and you consistently produce two valuable streams: renewable energy and high-quality by-products.