5 advantages of remanufactured gas engine spare parts and components

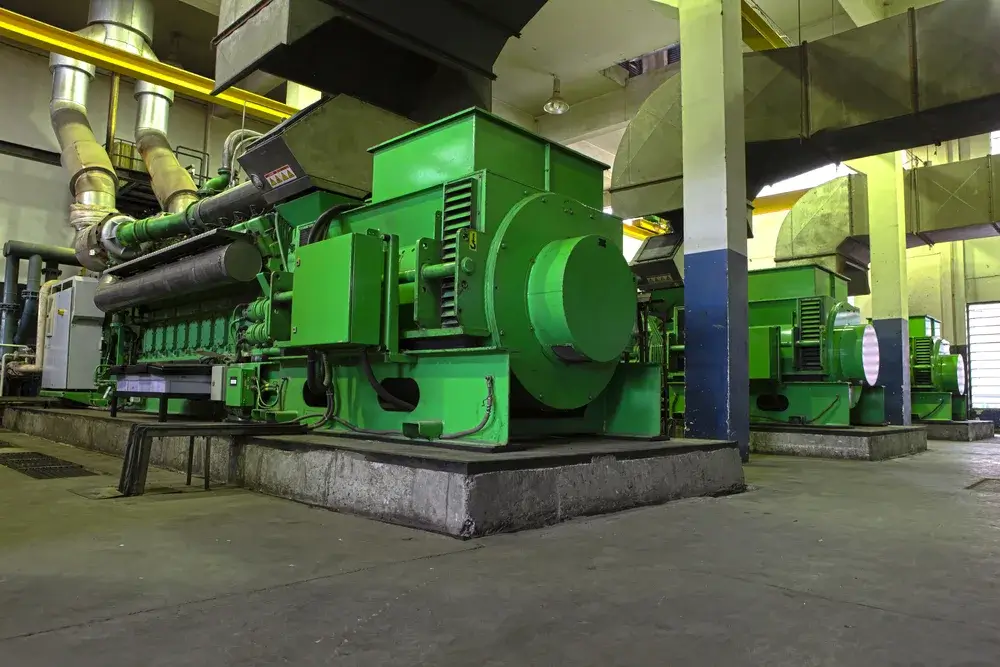

In the high-pressure environment of industrial energy generation, maintenance is more than just a chore. It is a strategic lever for profitability. Whether running a biogas plant or a large-scale IPP facility, operators constantly balance the need for reliability with the pressure to reduce operational costs.

As energy systems grow more complex and uptime becomes critical, a shift in mindset is occurring. Many operators are turning to remanufactured gas engine spare parts and components, not as a desperate fallback, but as a deliberate and cost-effective choice.

When backed by a condition-based overhaul strategy, remanufactured parts offer reliable performance, technical consistency, and financial efficiency, all while aligning with long-term sustainability goals.

Below, we highlight five key advantages of integrating remanufactured parts into your gas engine operation.

1. Cost savings without compromising quality

One of the most compelling advantages of remanufactured components is the cost-benefit ratio. Compared to brand-new parts, remanufactured gas engine spare parts and components typically come at a significantly lower price point, often saving operators 30% to 50% of the investment.

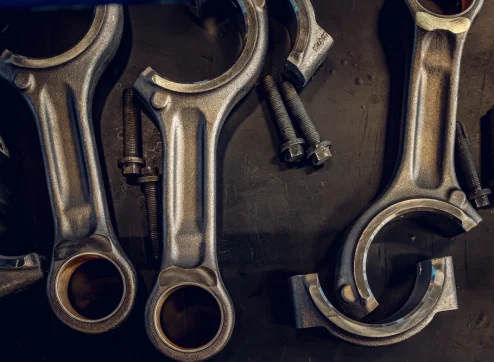

Professional standards ensure reliability

However, price must not come at the expense of function. When remanufacturing is done professionally, each component, whether it is a cylinder head or a connecting rod, is carefully inspected and rebuilt to meet original specifications.

This ensures that the part performs as reliably as a new component. For operators managing multiple units or complex facilities, these savings scale quickly, making it a smart option for both scheduled maintenance and unplanned repairs.

2. Environmental benefits and resource efficiency

In today’s energy sector, sustainability is no longer a buzzword, it is a requirement. Remanufacturing is not only a business decision but also an environmental one. By reusing existing high-quality materials (such as the engine block casting or the core of a turbocharger), the process conserves energy and raw resources that would otherwise go into producing entirely new parts.

This practice helps reduce waste, lowers the demand for raw materials like steel or aluminum, and significantly cuts down on the carbon emissions associated with full-scale production. For companies prioritizing sustainability, choosing remanufactured gas engine spare parts supports long-term environmental goals without compromising technical performance.

3. Availability and shorter lead times

In energy-critical operations, downtime is the ultimate enemy. One of the hidden advantages of remanufactured parts is their faster availability. While OEM production lines can require long lead times, especially for low-volume or legacy series, remanufactured components are often stocked or can be restored much faster than a new part can be cast and forged.

This is particularly relevant for:

- Legacy Engine Series: Where new parts are often phased out or difficult to source globally.

- Specialized Applications: Where custom configurations can lead to extensive delays in the OEM supply chain.

Utilizing remanufactured gas engine spare parts and components reduces the wait and gets your engine back up and running sooner.

4. Verified performance and compatibility

A common misconception is that “reman” means “uncertainty.” The opposite is true. When conducted under a controlled program, as offered by PowerUP, each component undergoes detailed inspection, cleaning, testing, and replacement where needed.

The validation process

Wear limits are measured against strict standards, and tolerances are checked with precision. This process ensures a high-quality outcome: parts that meet or exceed technical requirements, offer robust durability, and integrate seamlessly into the engine’s powertrain. From shortblocks to gensets, performance and reliability are thoroughly validated.

5. Long-term maintenance support with condition-based strategy

For operators of gas engines, whether in power generation, farming, or industrial applications, remanufactured components are an integral part of a sustainable maintenance strategy. Particularly when paired with a condition-based overhaul approach, they help extend the operational life of engines while keeping systems flexible and efficient.

Instead of adhering to rigid full replacement schedules, PowerUP focuses on actual wear and tear. This targeted method offers clear strategic benefits:

- Tailored Replacement: Only the components that strictly require attention are swapped, avoiding unnecessary costs.

- Waste Reduction: Functional parts remain in service, maximizing the utility of every asset.

- Maximum Value: Every euro invested goes directly into necessary performance improvements.

Optimize value and sustainability

Remanufactured gas engine spare parts and components reduce costs, support environmental goals, and keep systems running with fewer delays. Backed by PowerUP’s expertise and quality control, these components are a proven path to longer service life and better operational efficiency.

Looking for support with your engine’s next overhaul?