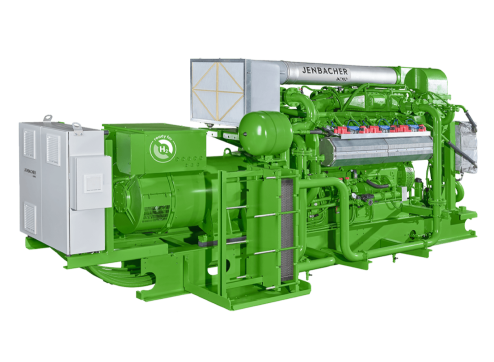

Inside the Jenbacher® Type 3 Series – The Global Workhorse

In the world of gas engines, there are machines that impress with sheer power, and those that become legends through sheer indestructibility. The Jenbacher Type 3 series undoubtedly belongs to the second category.

With thousands of units installed worldwide, this series is the backbone of decentralized power generation – especially in agriculture and for municipal utilities.

Why is the Jenbacher Type 3 series so popular? In this deep dive, we take a look under the hood. We analyze the technology that makes this engine the favorite of many biogas plant operators, and show how you can ensure that this classic continues to run profitably in the future with spare parts and upgrades from PowerUP.

The Recipe for Success: Robustness meets Efficiency

The Jenbacher Type 3 covers an electrical power range of approx. 500 to 1,100 kW. It thus occupies exactly the niche that is crucial for many biogas plants, small Combined Heat and Power (CHP) plants, and local microgrids.

What distinguishes this series is its technical maturity. In contrast to highly tuned aggregates that react sensitively to the smallest changes, the Type 3 is considered “forgiving”. It combines a solid mechanical structure with high efficiency – a compromise that in practice often guarantees the lowest operating costs (Total Cost of Ownership).

The most common models of the series are:

- J312: The 12-cylinder V-engine (approx. 500–600 kW).

- J316: The 16-cylinder (approx. 800 kW).

- J320: The 20-cylinder flagship (approx. 1,000 kW+).

Technology in Detail: Why the Type 3 is so Reliable

To understand why this gas engine is so long-lasting, it is worth taking a look at how Jenbacher engines work. The Type 3 uses proven concepts that have been perfected over decades.

Long-lasting Components

The engine block (crankcase) is extremely torsion-resistant. The crankshaft and connecting rods are generously dimensioned to withstand high firing pressures beyond 60,000 operating hours.

Optimized Cylinder Heads

The cylinder head is typically the Achilles’ heel of a gas engine. In the Type 3, it was consistently designed for thermal stability. The proven 4-valve technology ensures efficient gas exchange, while the design avoids “hotspots”.

The PowerUP Advantage: We offer cylinder heads suitable for Jenbacher Type 3 that are often even more resistant to cracking than the original design due to optimized materials.

Turbocharging and Mixture Cooling

The Type 3 works with modern turbocharging to extract maximum performance even from renewable gases with low calorific value. The mixture cooler (intercooler) ensures the optimal temperature before combustion, which reduces knocking tendency and increases electrical efficiency.

The King of Biogas and Landfill Gas

When we talk about the range of gases for Jenbacher engines, the Type 3 is typically the first choice for difficult fuels.

In agriculture, where biogas is produced from manure or maize silage, the gas quality often fluctuates. The methane content varies, and corrosive substances like hydrogen sulfide burden the material. High-performance engines of other series often go into fault mode here. The Type 3 keeps running.

Its robust design and flexible engine control make it ideal for:

- Biogas plants (Focus on robustness).

- Landfill gas utilization (Handling siloxanes).

- Sewage gas plants (Municipal wastewater treatment).

Maintenance and Service Life: A Second Life for the Type 3

Even a long-distance runner needs care. The maintenance intervals of the Type 3 are known throughout the industry for their length, but at some point the general overhaul (rebuild) is due.

Many operators are then faced with the question: Buy new or rebuild? Especially with the Type 3, remanufacturing is almost always worth it. The substance of the core engine is often so good that it easily achieves a second service life with new liners, pistons and overhauled heads.

In our article “Revitalizing Power” we explain in detail how we design this process at PowerUP. We offer not just standard overhauls for the Type 3, but targeted upgrades:

- Improved spark plugs for longer change intervals.

- Scraper rings (Anti-Polishing Rings) in the cylinder liners to reduce oil consumption and prevent carbon deposits on the piston.

PowerUP: Your Partner for the Type 3 Series

We know that the Jenbacher Type 3 is often the heart of your economic existence – be it on the farm or in the company. That is why we at PowerUP have specialized in offering the best alternatives for exactly this series.

As an independent service provider, we deliver:

- Spare Parts: Suitable for Jenbacher J312, J316, and J320. Quickly available and quality-tested.

- Shortblocks: Exchange engines to minimize downtime in the event of major damage.

- Expertise: Our technicians know every screw of this engine and help you raise even older models (from the GE era) to modern efficiency standards.

The Type 3 is a legend. We ensure it remains one.