How is biogas produced?

Biogas production is an ingenious method of extracting value from materials that are typically discarded. Whether it consists of animal manure from farms, food waste from kitchens, or wastewater from treatment plants, organic waste transforms into a powerful asset when processed correctly.

For operators of biogas plants and landfills, understanding this process is crucial. It is not just about waste management. It is about generating renewable energy that powers communities and industries.

In this article, we take a closer look at the anaerobic digestion process. We explain how biogas is formed, what conditions the microorganisms require, and how this fits into a circular economy model. Furthermore, we discuss how PowerUP solutions, suitable for Jenbacher®, MWM®, and other manufacturers, ensure your engine handles the resulting fuel efficiently.

What is biogas made from?

Biogas is produced from organic material, also known as feedstock. These materials are rich in biodegradable matter and come from various sources. The versatility of biogas systems allows them to utilize different inputs depending on the location and available raw materials.

Common feedstocks include:

- Agricultural waste: This includes animal manure, slurry, straw, and silage leftovers found in rural areas.

- Food waste: Kitchen scraps, expired groceries, and food industry by-products serve as high energy inputs.

- Sewage sludge: This is collected from wastewater treatment plants and municipal facilities.

- Industrial waste: Organic residues such as glycerin, dairy by-products, or distillery residues are valuable energy sources.

The key requirement is that the feedstock contains organic compounds like carbohydrates, fats, and proteins. The bacteria break these down in an oxygen-free environment. The more consistent and nutrient-rich the biomass, the more reliable the biogas production.

Biogas production: The anaerobic digestion process explained

The core of biogas production is anaerobic digestion. This is a biological process that happens when microorganisms, often called microbes, break down organic matter in the absence of oxygen.

It mimics the natural decomposition that occurs in swamps but does so in a controlled tank called a digester. This entire biogas production process happens in four main steps, which rely on different types of bacteria working in a balanced environment.

The four stages of fermentation are:

- Hydrolysis: Complex organic molecules are broken down into simpler compounds such as sugars and amino acids.

- Acidogenesis: These simple compounds are converted into volatile fatty acids, alcohols, carbon dioxide, and hydrogen.

- Acetogenesis: The intermediate products are further digested into acetic acid, CO₂, and hydrogen.

- Methanogenesis: Special microorganisms called methanogens convert these compounds into methane (CH₄) and carbon dioxide (CO₂).

These are the primary components of biogas. If the process becomes unstable due to pH changes or toxic substances, gas production can be affected significantly.

Inside the biogas plant: What happens in the reactor?

Typically, anaerobic digestion takes place inside a biogas plant reactor or digester. This is a sealed tank designed to maintain the right conditions for microbial activity. The digester is filled with organic material and kept at a consistent temperature.

Commonly used temperature ranges include mesophilic conditions around 35 to 40 degrees Celsius or thermophilic conditions around 50 to 55 degrees Celsius.

Inside the reactor, the material is mixed regularly. This distributes bacteria and prevents scum or sediment buildup. As the fermentation proceeds, gas accumulates in the top section and is piped off for storage or use. The remaining liquid or solid residue is known as digestate. It is removed periodically and often used as a natural fertiliser.

Depending on the scale of the system, the digester may be part of a larger facility that includes storage tanks, separators, and upgrading units.

Renewable natural gas: Upgrading biogas to biomethane

Raw biogas contains about 50 to 70 percent methane. The rest is mostly carbon dioxide plus small amounts of hydrogen sulfide, moisture, and other trace gases. For some applications, especially grid injection or use as vehicle fuel, this gas needs to be upgraded.

Biogas upgrading involves removing CO₂, water vapor, and impurities to increase the methane concentration to above 95 percent. This creates biomethane, also known as renewable natural gas (RNG).

Once upgraded, biomethane allows for flexible usage. It can be compressed or liquefied and injected into the natural gas grid. It serves as a sustainable energy source for heavy-duty vehicles or high-efficiency Combined Heat and Power (CHP) systems, just like fossil natural gas.

Factors that influence gas yield and quality

Several factors impact how much biogas is produced and how clean it is. Well-managed systems can produce high gas yields with minimal downtime. When gas composition is stable and free of contaminants, it is easier to control emissions and stay within environmental limits.

Key factors include:

- Type of feedstock: High-energy materials like fats tend to produce more gas, while woody inputs are harder to digest.

- Feedstock consistency: A steady supply supports stable microbial activity and prevents shock loads.

- Retention time: Longer retention generally leads to more complete digestion and higher methane production up to a point.

- Process temperature: Stable temperatures are vital as microbes are sensitive to fluctuations.

- pH balance: The system should stay slightly alkaline for optimal biogas production.

- Inhibitors: Substances like ammonia or sulfur compounds can interfere with the process and reduce methane content.

High-quality biogas contributes to a more environmentally friendly impact. It reduces wear on engine components and ensures the long-term viability of biogas systems.

What is the difference between natural gas and biogas?

What is the difference between biogas and natural gas? This article provides a detailed comparison of their origin, composition (methane vs CO2), calorific value, and environmental impact (fossil fuel vs renewable).

Environmental and operational benefits

Producing biogas offers many environmental and operational benefits. It reduces methane emissions from decomposing waste and lowers dependence on fossil fuels. This supports local energy production and security.

The process also creates a closed loop. The digestate left after gas production can be used as fertilizer, which replaces synthetic options. This further reduces the carbon footprint. By using existing by-products, biogas serves as a vital renewable energy source and supports a circular economy where resources are reused and greenhouse gas emissions are kept in check.

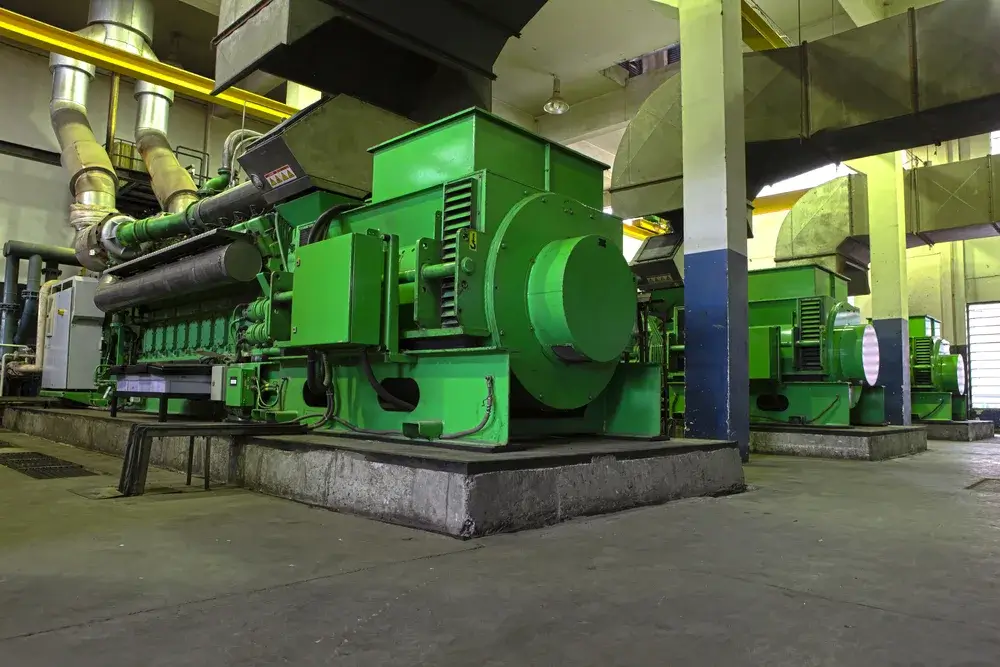

PowerUP’s role in supporting biogas energy systems

Biogas is a valuable biofuel, but it comes with technical challenges. Gas quality varies depending on feedstock and process control. Impurities like hydrogen sulfide and moisture can affect engine components and combustion efficiency.

At PowerUP, we work with operators who use biogas, landfill gas, or sewage sludge gas in cogeneration systems. Our focus is on maintaining performance even when gas conditions are less than ideal.

We support your operation by:

- We help fine-tune engines to handle variable gas compositions effectively.

- Our gas engine spare parts are suitable for Jenbacher®, MWM®, Caterpillar®, MAN®, and other manufacturers. They are designed for durability in aggressive biogas environments.

- We extend engine life by replacing parts based on actual wear rather than rigid schedules.

- We track system behavior to detect early signs of inefficiency.

With the right support, biogas plants can operate reliably and deliver consistent electricity generation. We help you make better use of locally available sources of energy.