Revitalizing Power — Everything about Jenbacher® rebuilds

Every high-performance engine reaches a critical crossroads in its life-cycle. Usually, around the 30,000 or 60,000 operating hours mark, regular maintenance is no longer enough to guarantee the efficiency and reliability you rely on.

For operators of Jenbacher gas engines, this moment poses a multi-million dollar question: Do you invest in a brand-new engine, or do you breathe new life into your existing asset?

The answer is rarely simple, but for those focused on cost-efficiency, sustainability, and speed, a professional Jenbacher rebuild (general overhaul) is often the superior strategy.

In this comprehensive guide, we move beyond the basics. We explore the deep technical details of remanufacturing, analyze the Total Cost of Ownership (TCO) for IPPs and biogas operators, and demonstrate how PowerUP turns an aging engine into a high-performance generator set that often outperforms its original factory specs.

The Economics of Rebuilding: ROI and TCO Explained

Why do leading energy providers and industrial operators choose overhauls over new equipment? The decision is driven by the bottom line. A new Jenbacher engine represents a massive CAPEX (Capital Expenditure) and often comes with lead times of 12 months or more from the OEM.

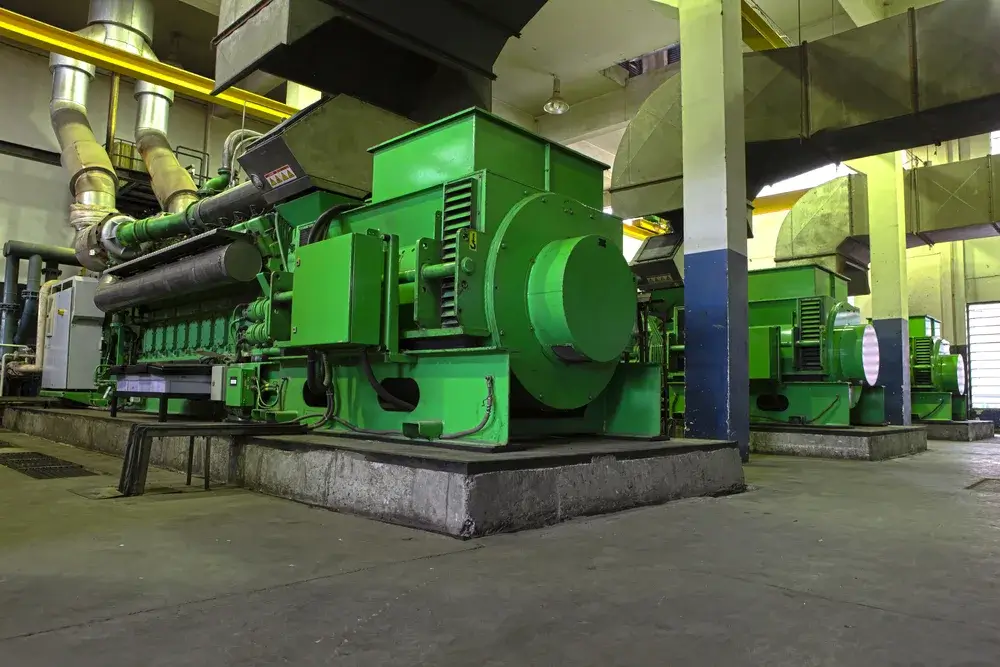

A rebuild, by contrast, leverages the massive value already sitting in your engine room. The heavy cast-iron components—the engine block, the crankshaft, the connecting rods—are built by Jenbacher Werke in Austria (Österreich) to last for decades. Discarding them is not just wasteful; it’s bad business.

Financially, the advantages are significant. A high-quality rebuild typically costs 60-70% of a new engine, releasing capital for other energy solutions. Furthermore, in many jurisdictions, a rebuild is classified as maintenance (OPEX) rather than a new asset investment (CAPEX), offering potential tax benefits.

From a sustainability perspective, reusing these core components reduces the carbon footprint associated with manufacturing and transporting tons of new steel, aligning directly with global Net-Zero goals.

The Ultimate Guide to Jenbacher® Gas Engines

Discover everything about INNIO Jenbacher engines: From Type 2 to Type 9, biogas, MyPlant, and cogeneration. Maximize your power generation with PowerUP.

The Rebuild Spectrum: Choosing Your Scope

Not every engine needs the same treatment. Depending on your downtime tolerance and budget, we offer three precise levels of remanufacturing.

1. Shortblock (Rumpfmotor) – The Core

The shortblock is the foundation of the engine. It includes the refurbished engine block, crankshaft, camshaft, bearings, connecting rods, and pistons. This option is best suited for operators who have capable on-site technicians available to reinstall cylinder heads and ancillary parts themselves. The primary advantage here is the cost-effective restoration of the engine’s mechanical heart without paying for peripheral labor.

2. Longblock – The “Ready-to-Run” Core

The longblock builds on the shortblock architecture but arrives pre-assembled with cylinder heads, the valve train, and often the oil pump and timing gears. This solution is ideal for rapid on-site exchanges, as it drastically reduces the labor and risk involved in assembling critical components in a non-cleanroom environment. It offers the highest balance between cost efficiency and installation speed.

3. Genset (Complete Aggregate) – The Total Reset

This is the “peace of mind” package where the entire unit, including the generator, couplings, and base frame, is overhauled. This approach is recommended for plants reaching the 60,000 or 80,000-hour mark where peripheral components are also fatigued. The result is a completely revitalized power plant asset with a warranty comparable to a new machine.

The “Zero-Downtime” Solution: The Exchange Program

For an Independent Power Producer (IPP) utilizing pipeline gas or a biogas farmer, every hour of downtime means lost revenue and potential penalties. Waiting weeks for your own engine to be rebuilt is often not an option.

The solution lies in the Rolling Exchange (Das rollierende Verfahren). PowerUP maintains a stock of overhauled Jenbacher shortblocks and longblocks. We ship a revitalized engine to your site before you shut down, allowing you to swap the engines immediately. Once the swap is complete, we take your old core back, overhaul it, and place it in stock for the next customer. This “Swing Engine” concept ensures that your power generation continues with minimal interruption, reducing downtime to just a few days instead of weeks.

The Rebuild Process: From Core to Commissioning

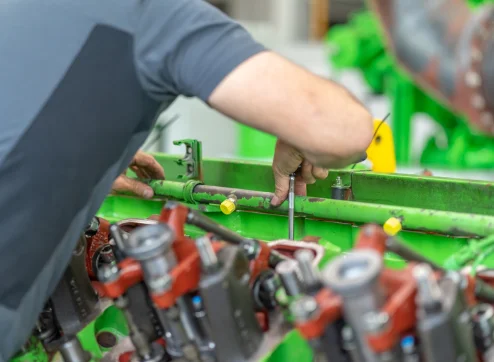

A Jenbacher rebuild at PowerUP is a meticulously controlled industrial process. We don’t just “fix” engines; we remanufacture them according to strict protocols.

- Disassembly & Cleaning: The engine is stripped to its last bolt. Every part is chemically cleaned to remove carbon deposits and oil residue.

- NDT Testing (Non-Destructive Testing): This is critical. We use magnetic particle and ultrasonic testing to scan the crankshaft and engine block for microscopic cracks that the naked eye cannot see. Only flawless cores move forward.

- Machining: Cylinder liner seats are re-machined, and crankshafts are polished or ground to precise undersize dimensions if necessary.

- Assembly with Upgrades: The engine is reassembled in a clean environment. This is where we install latest technologies to improve performance.

- Painting & Preservation: The engine receives a protective coating to withstand harsh industrial environments.

- Quality Control: Every dimension is documented. We ensure the engine meets strict tolerances before it leaves our workshop in Tirol.

Upgrade instead of just Exchange: Better than New?

Why settle for the technology of 2010 when you can have the technology of today? As an independent distributor and developer, PowerUP integrates improvements that OEM standard parts might miss.

Key Technical Upgrades:

- Optimized Pistons: We use pistons with advanced coating technologies and modified geometries to reduce friction and improve combustion.

- Anti-Polishing Rings: For Jenbacher Type 3, 4, and 6, we can install cylinder liners with scraper rings. These prevent carbon build-up on the piston crown, significantly reducing oil consumption and extending the life of the lube oil.

- Robust Cylinder Heads: Our overhauled cylinder heads for biogas applications feature hardened valve seats to resist the corrosive effects of hydrogen sulfide and landfill gas (Deponiegas).

The Impact of Gas Quality on Rebuild Scope

The fuel you burn dictates the wear you face. We tailor the rebuild scope to your specific energy carriers:

| Gas Type | Primary Wear Factor | Rebuild Focus |

| Natural Gas (Erdgas) / Pipeline Gas | Mechanical friction, thermal load | Focus on maintaining tight tolerances and thermal efficiency. Standard components often suffice. |

| Biogas / Sewage Gas | Chemical corrosion (Acid), fluctuating methane | Use of corrosion-resistant bearings and valves. Special attention to gas mixer and intercooler condition. |

| Landfill Gas (Deponiegas) | Siloxanes (glass-like deposits), extreme abrasion | Frequent cylinder head exchanges required. Piston rings must be highly durable to scrape away deposits. |

| Syngas / Wood Gas | Tar deposits, unstable combustion | Customized compression ratios and robust ignition systems (spark plugs) are essential. |

Why Partner with PowerUP?

While INNIO Jenbacher builds excellent engines, the aftermarket is where PowerUP shines. We are not bound by rigid corporate structures, but by our promise to keep your engine running.

Our independence allows us to offer unbiased advice: if a part doesn’t need replacing, we don’t replace it. We maintain a strategic stock of critical spare parts and cores that might have months of lead time elsewhere, ensuring high availability.

Furthermore, our team consists of former Jenbacher engineers and technicians who know these machines inside out. From Austria to the Americas, our service network supports energy systems worldwide with speed and technical excellence.

Ready to Revitalize? Don’t let an aging engine threaten your power generation revenue. Whether you need a quote for a 60,000-hour overhaul or urgent spare parts, we are ready.