The main components of biogas plants and their significance

Biogas plants are a cornerstone of the renewable energy landscape. They turn organic waste into a reliable energy source. However, for the operator, they represent a massive technical challenge. These facilities are complex systems where biology, chemistry, and mechanics must interact perfectly.

If one component fails, the entire process can stall. This leads to downtime and revenue loss. Understanding the hardware is the first step to mastering the operation.

This article focuses on the machinery that drives the waste-to-energy process. We take a detailed look at the core components and explain why their reliability is crucial for your operational stability.

Biogas Plants: A Comprehensive Guide to Biogas Production

Our comprehensive guide to biogas plants. Learn how a biogas plant works, from anaerobic digestion in the digester to biogas production from organic waste, animal manure, and food waste.

Overview of the Main Components

A biogas plant is a system of interconnected components, each with a specific role. From the moment the feedstock arrives until the final energy is produced, the material is processed, digested, and converted. These components work together to manage the anaerobic digestion process and handle its outputs.

Component 1: Feedstock Preparation and Substrate Processing

This is the starting point. All organic materials, known as feedstock or substrate, must be prepared before they enter the digester. This component is crucial for an efficient fermentation process. This stage involves:

- Receiving and storing the biomass, which can include animal manure, food waste, energy crops, or other organic waste.

- Shredding and crushing solid materials (like crop residues) to increase the surface area for the microorganisms.

- Homogenization, where different feedstocks (like liquid manure and solid organic materials) are mixed into a consistent, pumpable slurry.

- Removing contaminants like plastics or stones that could damage the system.

Proper substrate processing ensures a stable feedstock for the microorganisms, which is the first step to optimized biogas production.

Component 2: The Digester (Fermenter or Bioreactor)

The digester, also known as a fermenter or bioreactor, is the centerpiece of every biogas plant. It is a large, sealed, and often heated tank where the anaerobic digestion process occurs.

Inside this component, a complex community of microorganisms breaks down the prepared organic materials in the absence of oxygen. The fermenter provides the optimal conditions (temperature, mixing) for this biological activity. This process can take weeks and results in the production of raw biogas, which is primarily a mixture of methane and carbon dioxide.

Component 3: Gas Storage and Gas Treatment

As the raw biogas is produced in the bioreactor, it needs to be captured, stored, and often cleaned. This involves several components:

- Gas Storage: The gas is often stored in a flexible membrane on top of the digester or in a separate gas storage tank. This buffers fluctuations in gas production, ensuring a steady supply to the gas engines.

- Gas Treatment: Raw biogas contains impurities that are harmful to engines, chiefly hydrogen sulphide (H2S), which is highly corrosive, and moisture. The gas treatment or gas purification system removes these contaminants. This vital step, especially desulphurisation, protects the downstream equipment.

- Upgrading (Optional): For some applications, the gas undergoes further gas purification, known as upgrading. This process removes the carbon dioxide, producing high-purity biomethane that can be injected into the natural gas grid.

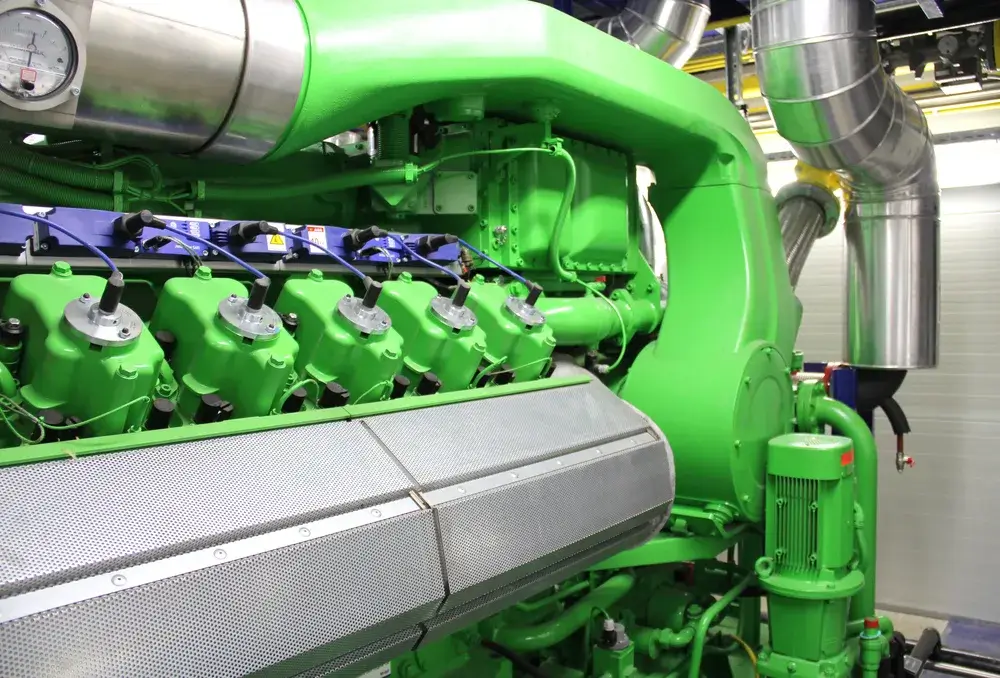

Component 4: Energy Generation: The Combined Heat and Power (CHP) Unit

This component is where the profit is generated. The Combined Heat and Power (CHP) unit, also known as a cogeneration plant, is the engine of the facility. This component is typically a specialized gas engine designed to run on raw biogas. It performs two functions simultaneously (cogeneration):

It captures the immense waste heat from the engine’s cooling system and exhaust. This thermal energy is used to heat the digester (maintaining the fermentation process) and to heat nearby buildings, maximizing the overall efficiency of the energy generation.

It burns the methane to spin a generator, creating electricity for on-site use or for sale to the grid.

How does combined heat and power (CHP) work? Technology in Detail

How does a CHP plant work? We explain the technology: From the prime mover and generator to heat recovery. Learn how to lower energy costs and emissions.

Component 5: Digestate Storage (The Final By-product)

After the anaerobic digestion process is complete, the leftover material, known as digestate or fermentation residues, is pumped out of the digester. This is the main by-product of the plant. This digestate is stored in a large, sealed lagoon or tank. It is not waste.

This by-product is a nutrient-rich, low-odor liquid fertilizer, superior to raw manure. This final component allows the biogas plant to return valuable nutrients to the soil, creating a closed-loop system for agriculture.

Why High-Quality Components Matter

The operational stability of a biogas plant is a chain where every link matters. A failure in a single component, from a pump in the feedstock preparation to a sensor in the digester, can halt the entire energy generation process. This is especially true for the CHP unit.

The gas engine is the most complex and hardest-working component. Its reliability is directly linked to the plant’s profitability. High-quality components are not just an option; they are a requirement for continuous, efficient, and profitable operation.

High-Performance Components for Your Biogas Plant from PowerUP

Elevate your biogas plant’s performance with high-quality components from PowerUP. While all components are vital, the gas engine in your CHP unit is the most critical for your revenue. Technology is our drive, efficiency our focus.

We provide a wide range of high-performance gas engine spare parts suitable for Jenbacher and MWM engines, engineered to withstand the harsh conditions of biogas. Our services, including gas engine upgrades and gas engine repairs, keep your operations at peak efficiency.

Trust PowerUP to provide reliable solutions tailored to your biogas plant’s most critical component, enhancing both productivity and sustainability.