The 5 Best Sources for Biogas – Transforming Waste into Power

Organic waste builds up quickly—on farms, in food production, and at wastewater plants. For many, managing this material is complex, costly, and time-consuming. But viewed through a different lens, this “waste” transforms into something entirely different: a valuable form of sustainable energy.

Biogas production turns a disposal burden into a profit center. It helps businesses and municipalities reduce greenhouse gas emissions, save resources, and generate local renewable electricity. However, not all waste is created equal. The source of energy directly impacts the efficiency of your plant and the longevity of your gas engine.

In this article, we explore the sources of biogas, dive into the anaerobic digestion process, and explain why knowing your feedstock matters more than you might think for stable power generation.

What is biogas and where does it come from?

Biogas is a renewable fuel made primarily of methane (CH₄) and carbon dioxide (CO₂). It is produced when microorganisms (or microbes) break down organic material in an oxygen-free environment. This biological process is known as anaerobic digestion.

The material used in this process is called feedstock or biomass. Unlike fossil fuels (like coal or natural gas extracted from the ground), biogas relies on the continuous cycle of life and decay.

The production process explained

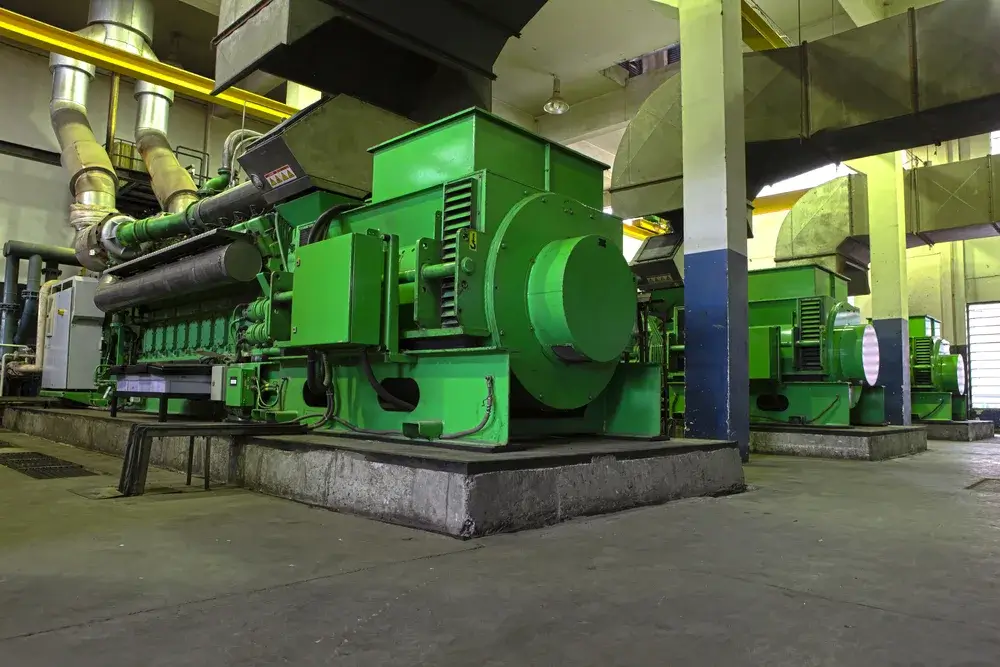

A typical example of biogas production would be a farm that uses animal manure or slurry in a digester to power a Combined Heat and Power (CHP) unit.

- Fermentation: The raw material is placed in a sealed tank (digester) in the absence of oxygen.

- Digestion: Bacteria break down the organic matter.

- Capture: The rising gas is captured as biofuels for various end uses, such as electricity generation or heat.

- Residue: The remaining digestate serves as a nutrient-rich fertilizer or compost.

While natural gas is a finite resource, biogas is a renewable energy source that solves waste management challenges while producing power.

The 5 best sources for biogas

It is important to know where biogas comes from because the source of the feedstock directly affects the quality, consistency, and efficiency of biogas plants. Different sources of biogas vary in energy content, moisture levels, and the presence of contaminants.

These differences directly influence the efficiency of biomethane production, how stable the digestion process will be, and what kind of gas cleaning or engine adjustments are required. Let’s take a closer look at the five most effective and practical sources.

1. Animal manure

Animal manure (and animal waste) is one of the most widely used biogas sources, particularly on farms and in rural areas. It is rich in organic material, produced in large quantities, and often readily available on-site near where it will be used.

- Pros: Manure has a relatively stable composition, which helps maintain a steady digestion process.

- Optimization: It is commonly used in co-digestion with other materials like food waste or crop residues to improve gas output. This mix creates a robust renewable source for cogeneration.

2. Food waste

Food waste has a high methane potential, especially when it comes from commercial kitchens, food processing plants, or municipal waste systems. It is energy-dense and breaks down quickly, making it a highly efficient feedstock for biomethane production.

- Challenge: It often requires preprocessing like separation, grinding, or pulping to ensure it is free of non-organic contaminants and suitable for digestion.

- Impact: Diverting food from landfills significantly reduces methane emissions that would otherwise occur naturally, actively fighting climate change.

3. Agricultural residues

Agricultural residues include agricultural waste and crop leftovers like straw, corn stover, and grass silage. These materials are abundant and can be collected from existing farm operations.

- Utility: While their gas yield per ton can be lower than fats or food waste, they are a practical and cost-effective addition to biogas systems, particularly when combined with manure.

- Sustainability: Using residues ensures that the primary crop is used for food, while the by-products drive energy production.

4. Sewage sludge

Sewage sludge, a byproduct of wastewater treatment plants, is another consistent biogas source. Many municipal plants already have anaerobic digesters on site to handle this material.

- Consistency: It is a predictable and centralized feedstock.

- Quality: The resulting biogas may require additional cleaning or upgrading due to the presence of sulfur, siloxanes, and other impurities before it is used for electricity generation or injected into the natural gas grid.

5. Organic industrial waste

Industries such as breweries, distilleries, dairies, and food processors generate large amounts of industrial waste. Materials like whey, spent grain, and wash water are often high in sugar, fat, or starch content, which means high gas yields.

Because these operations already handle organic materials at scale, integrating biogas production into their processes is both efficient and economical. It turns a disposal cost into a source of energy.

Anaerobic digestion explained—Process, Benefits, and Uses

Imagine turning your biggest disposal headache into your most valuable asset. Anaerobic digestion makes this possible. In this article, we explain how this biological process transforms organic waste into renewable energy. Discover how you can close resource loops and why optimized engines, suitable for Jenbacher®, MWM®, and other manufacturers, are the heart of this sustainable ecosystem.

From source to engine: The PowerUP advantage

Biogas quality can vary significantly depending on the source. A system running on food waste, for example, will face different combustion conditions than one powered by manure or landfill gas. Fluctuations in methane content or impurities like hydrogen sulfide can wreak havoc on an engine.

That is why engine performance depends not only on design but also on how well systems adapt to these changing conditions. At PowerUP, we work closely with operators to maintain stable, efficient energy output—even when gas composition fluctuates.

We support your operation with:

- Specialized Spare Parts: Components like cylinder heads and spark plugs suitable for Jenbacher®, MWM®, and other manufacturers, designed to withstand aggressive biogas environments.

- Condition-Based Overhaul: We help fine-tune engines for consistent combustion and reduce the risk of downtime through condition-based maintenance.

- Upgrades: Modern control systems to optimize air-to-fuel ratios in real-time.

By combining technical expertise with a deep understanding of biogas systems, we support energy producers in getting the most out of every feedstock they use.