Everything you need to know about Captive Power Plants – The Ultimate Guide to Energy Independence

When electricity prices explode and the public grid becomes unstable, standard solutions are no longer enough. This is where Captive Power Plants (CPP) enter the stage. For energy-intensive industries, they are not just an option, but the backbone of production. They combine energy independence with cost efficiency – a decisive competitive advantage in volatile markets.

For production managers and operators of large industrial facilities, a Captive plant is often the first choice to escape rising tariffs and unpredictable outages. In a global landscape where energy supply is increasingly fragile, relying solely on the national grid can be a reckless gamble. A dedicated power source ensures that your operations continue seamlessly, regardless of external disruptions.

However, owning a power plant changes your role. You are no longer just a consumer; you become an operator. With great power comes great responsibility regarding operation, maintenance, and compliance.

In this comprehensive guide, we illuminate the world of Captive Power Generation – from the technical nuances of grid-connected systems to the integration of renewable energy, showing how you secure the availability of your power stations with services from PowerUP.

What is Captive Power Generation?

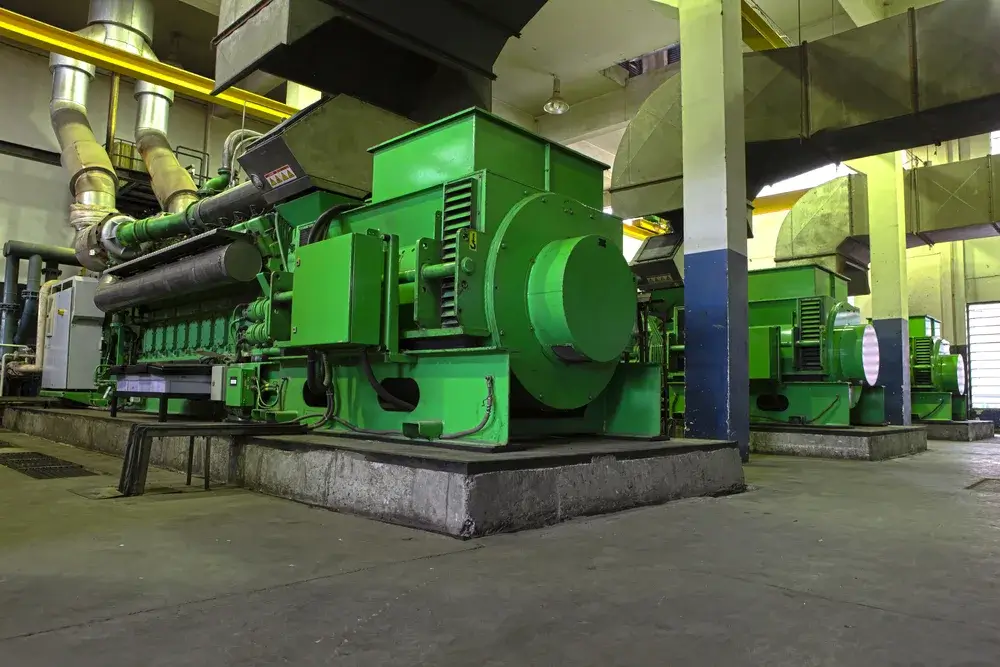

Simply put: Captive Power Generation is the production of electricity by a company for its own use. Unlike large utilities that feed massive amounts of energy into the high-voltage grid, a Captive Power Plant is located directly on-site—right where the energy is consumed.

This form of distributed generation allows factories, data centers, refineries, or remote mining operations to cover their energy demand independently. By eliminating the distance between generation and consumption, transmission losses are minimized, and efficiency is maximized. Depending on the local infrastructure and regulations, these plants operate in two main modes:

Off-grid (Island Mode): The plant runs completely isolated from the public net. This setup is common in remote areas where grid extension is too costly or in regions where the grid is too unreliable to support sensitive machinery.

Grid-connected: The system runs parallel to the grid. This offers a safety net: if the captive plant requires maintenance, the grid supplies power. Conversely, if the plant generates excess energy, it can often be fed back into the grid, turning a cost center into a revenue stream.

The goal is always a secure power supply. Whether using natural gas engines, utilizing biomass from production waste, or implementing modern hybrid power solutions – the control over your energy sources lies 100% with you.

IPP? CPP? The Difference Explained

In the energy sector, abbreviations often cause confusion. It is crucial to distinguish between an Independent Power Producer (IPP) and a CPP, as their business models and operational goals are fundamentally different.

The CPP (Self-Consumer)

The core characteristic of a Captive Power Plant (CPP) is that the owner of the plant is also the consumer. Imagine a large textile manufacturer in Gujarat, utilizing a bank of gas engines to power hundreds of weaving looms. This is a CPP.

- Primary Goal: Keeping production running, ensuring quality through stable voltage, and lowering internal electricity costs.

- Economics: The investment is justified by the savings on electricity tariffs and the avoidance of production losses.

The IPP (Energy Seller)

In contrast, an IPP is a commercial entity whose sole business is generating and selling electricity. They build power plants to sell the output to third parties—usually state utilities or large industrial parks—via a Power Purchase Agreement (PPA).

- Primary Goal: Maximizing the sale of kilowatt-hours (kWh) to generate profit.

- Economics: Their success depends on the spread between fuel costs and the selling price defined in the PPA.

This distinction matters because regulatory requirements and tariffs differ massively. While IPPs navigate complex grid codes and feed-in regulations, captive plants often enjoy tax benefits or exemptions because they relieve the burden on the public infrastructure.

The Advantages of Captive Power Plants

Why should a company take on the complexity of investing in its own power generation? The answer lies in the strategic triangle of cost, security, and sustainability.

1. Cost-Effective Operations

Industrial electricity tariffs often include heavy taxes, transmission fees, and cross-subsidies. By generating your own power, you bypass these markups. A CPP often produces electricity at a distinctively lower Levelized Cost of Electricity (LCOE) compared to the grid price. Cost efficiency is immediate, especially for 24/7 operations where peak-hour tariffs can be crippling.

2. Protection against Volatility

Outages cost the global industry billions annually. For a glass manufacturer, a 5-minute blackout can ruin an entire production batch and damage the kilns. A captive plant eliminates this risk. You are immune to grid fluctuations, brownouts, or load shedding. Your power quality is determined by your own equipment, not by an overloaded public substation.

3. Sustainability Goals

Modern captive power solutions allow you to actively manage your carbon footprint. You are not forced to accept the “grey” energy mix of the grid. By integrating clean energy sources, switching from coal to natural gas, or preparing for hydrogen, companies can faster reach their Net-zero targets. You control the emissions logic of your product.

Captive Power Plants vs. CHP Plants – A Technical Distinction

These terms are often used synonymously, but there is a technical difference that significantly affects your Return on Investment (ROI).

Standard Captive Power (Electricity Only)

A standard Captive Power Plant typically focuses on electricity generation. A standard gas engine generator converts the energy in the fuel into electricity, but the laws of thermodynamics dictate that a significant portion of this energy is turned into heat.

In a pure power plant, this heat is vented into the atmosphere, leaving the electrical efficiency typically around 40-45%.

Combined Heat and Power (CHP)

A Combined Heat and Power (CHP) plant, or Cogeneration, refuses to let this energy go to waste. It captures the waste heat from two main sources:

- Engine Jacket Water: Ideal for heating buildings or low-temperature processes.

- Exhaust Gas: Perfect for generating industrial steam or hot water.

By utilizing this thermal energy, the total system efficiency jumps to over 90%. This is the gold standard for paper mills, chemical plants, food processing, or district heating. By adding absorption chillers, the heat can even be used for cooling (Trigeneration), making it perfect for data centers or office complexes in hot climates.

Energy Sources: From Fossil Fuel to the Energy Transition

The engine technology in captive plants is versatile and agnostic to the fuel source, provided it is configured correctly.

The Shift from Fossil Fuels

Historically, diesel and coal were the drivers of captive power, but high emissions and volatile fuel prices have pushed them out.

Today, natural gas is the bridge technology. It burns cleaner, produces less CO2, and engines like the Jenbacher Type 6 or MWM TCG series are highly optimized for it.

Renewable Energy & Hybrid Power

The energy transition is pushing for hybrid power systems. This setup combines reliable gas engines with solar power (PV) and energy storage (BESS).

Solar power provides cheap, green energy during the day but is volatile.

The gas engine ramps up instantly when clouds pass or the sun sets to fill the gap.

The Result: A reliable, low-carbon power supply that balances the intermittency of renewables with the stability of thermal generation.

Applications: Where Captive Power Dominates

Certain industries cannot function without the reliability of CPPs.

Data Centers

In a digital world, data centers require personal data and cloud services to be available 24/7. A power failure here is not just an inconvenience; it is a liability. Data centers use massive captive power generation capabilities to ensure uptime.

Key Requirement: “Fast start” capability to pick up the load the moment the grid fails.

Role: Providing primary or N+1 redundant backup power.

Textiles and Heavy Manufacturing

Industries in regions like Gujarat (India) or remote mining areas in Australia rely on CPP to avoid production stops. Energy-intensive processes like smelting or weaving cannot tolerate voltage dips.

The Risk: A frequency drop in the grid can cause threads to break or motors to trip, leading to hours of downtime.

The Solution: A captive plant ensures a “clean” sine wave and stable frequency for sensitive machinery.

Maintenance and Efficiency: Downtime Costs a Fortune

For a CPP operator, a standing engine is the worst-case scenario. The costs for a day of failure often exceed the cost of maintenance for an entire year. Therefore, maintenance strategies must be aggressive and preventive. While EPC (Engineering, Procurement, Construction) contractors build the plant, keeping it running requires specialized attention.

Gas engines require regular service intervals, and the general overhaul at 60,000 hours is a major project where multi-ton components are dismantled. PowerUP supports here with solutions designed to save time:

- Exchange Components: Instead of waiting weeks for a cylinder head to be refurbished, we deliver already overhauled, “ready-to-run” parts directly to the site.

- Shortblocks: For major failures, we swap the entire core engine via Shortblocks, reducing downtime from weeks to days.

- Upgrades: We modernize control systems to handle island mode (off-grid) better or improve the engine’s tolerance for fluctuating gas qualities like biomass.

PowerUP: Your Partner for Energy Independence

Anyone operating a Captive Power Plant needs not just a parts supplier, but a partner with logistics competence and technical depth. Technology is our drive, efficiency our focus. We at PowerUP have aligned our warehouse and processes with the specific needs of CPP operators:

- Availability: We keep critical spare parts (spark plugs, liners, filters, gaskets) in stock to minimize lead times.

- Independence: We offer agile alternatives to the often rigid maintenance contracts of manufacturers (OEMs).

- Efficiency: We optimize your engine for biomass or natural gas to squeeze every kilowatt out of the fuel.

Your power supply is your lifeline. We ensure it flows efficiently, reliably, and sustainably.