Combined Heat and Power: Benefits and Challenges in an Honest Check

Anyone considering purchasing or modernizing an energy plant will sooner or later be confronted with superlatives: maximum efficiency, green future, independence. That sounds excellent, but as a responsible entrepreneur, farmer, or technical manager, you know that every coin has two sides. An investment of this magnitude requires a cool head and an honest assessment of the benefits of combined heat and power (CHP)—as well as its challenges.

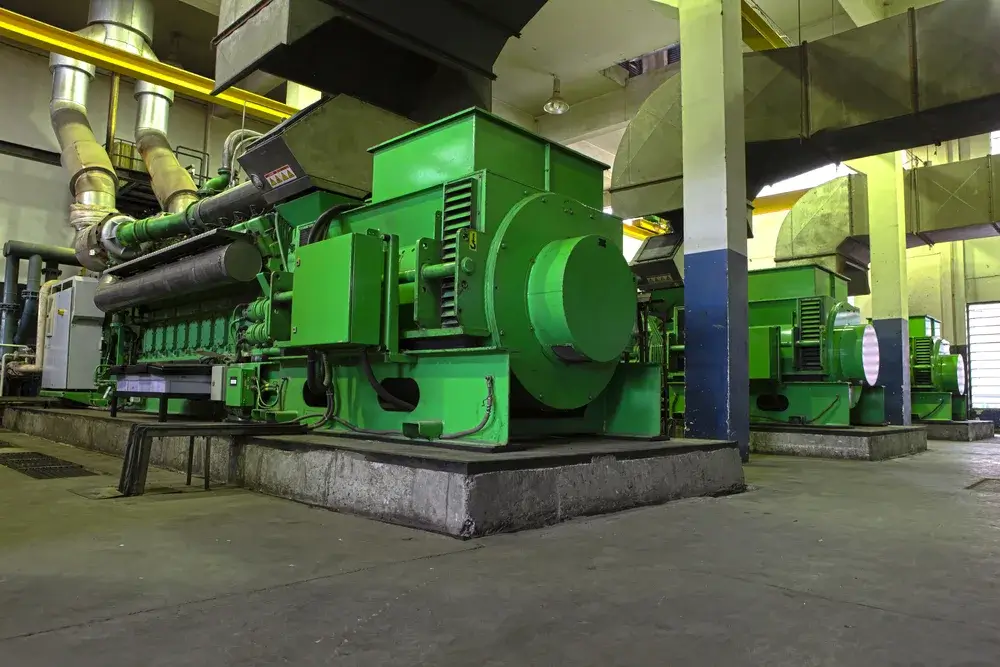

Technology is our drive, efficiency is our focus. At PowerUP, we know not only the glossy sides of the brochures but also the rough everyday life in the engine room.

In this article, we put the cards on the table: What speaks for the technology—and how do you master the hurdles that might speak against it?

The 8 Benefits: Why CHP is the Global Standard for Efficiency

Before we address the challenges, it is crucial to understand why the benefits of CHP are recognized worldwide and why governments incentivize this technology. It is not just about generating power; it is about reshaping how your business consumes resources.

1. Enormous Energy Efficiency

The most weighty advantage lies in physics itself. In separate generation processes found in conventional power plants, up to 60% of the energy used often vanishes unused as waste heat. A CHP plant changes this calculation fundamentally. Since the heat is extracted directly on-site, you achieve total efficiency levels of up to 90%. Unlike conventional plants, this method utilizes waste heat to heat buildings or support industrial processes, lowering your company’s primary energy factor drastically.

2. Significant Cost Reduction

Energy markets are more volatile than ever. By generating your own power, the Levelized Cost of Electricity (LCOE) is often significantly lower than the industrial electricity price from the grid. This is particularly beneficial in industrial areas and residential communities where energy costs comprise a significant portion of operational expenses. It makes your production costs calculable and robust against market shocks.

3. Enhanced Security of Energy Supply

For critical infrastructure like hospitals, data centers, or production facilities, a blackout is not an option. Many CHP systems are designed to be “island-capable”. This means that if the public grid fails due to storms or instability, your plant disconnects and continues to supply your operation autonomously. This reliability serves as a crucial backup system to maintain power supply in emergencies.

4. Independence from External Providers

By producing on-site, you reduce the amount of power you need to “transport” through the public grid. This promotes regional energy independence and reduces the risk of shortages caused by geopolitical uncertainties. You become less reliant on external energy sources and volatile market prices, gaining control over your own energy destiny.

5. Integration of Renewable Energies

CHP is the perfect partner for the energy transition. While solar energy and wind power fluctuate—delivering little energy during dark, calm winter days—the CHP unit delivers reliable heat and power. It compensates for the fluctuations in the availability of renewables, ensuring a consistent energy supply and increasing the share of clean energy sources in the grid.

6. Reduced Environmental Impact

Even when running on natural gas, the high efficiency means significantly less CO2 per kWh compared to coal or older grid mixes. By utilizing sustainable energy sources such as biomass or biogas, CHP further minimizes the environmental impact. This reduction of greenhouse gases is a vital step in combating climate change and helps companies meet their ESG targets immediately.

7. Revenue through Grid Feed-in

If you produce more electricity than you consume, you can feed it into the grid. In many regions, this is remunerated—for example, under specific Feed-in Tariffs in Europe or regulations like PURPA in the US. This turns your power plant into a profit center rather than just a cost center.

8. Promotion of Decentralization

Deploying CHP plants promotes a decentralized distribution of energy production. Instead of relying on a few massive power stations, energy is generated directly at the point of consumption. This strengthens the local energy infrastructure, reduces transmission losses, and enhances the resilience of the entire energy system against large-scale disruptions.

The 4 Challenges: Hurdles and How PowerUP Solves Them

Where there is light, there is shadow. Critics often cite high costs and technical complexity. Here is the reality check and our answer to these challenges.

Challenge 1: Complexity and High Investment Costs (CAPEX)

Acquiring a CHP unit is a hurdle. The acquisition and installation of necessary equipment, such as engines, generators, and heat exchangers, require a substantial investment. For smaller businesses, this capital expenditure can be daunting.

The PowerUP Solution: You don’t always have to buy new. We specialize in fair-value maintenance and general overhauls. A shortblock exchange or a targeted upgrade of your existing plant often costs only a fraction of a new engine. Plus, our long-lasting spare parts suitable for MWM or Jenbacher engines reduce running costs (OPEX), improving the Return on Investment (ROI) significantly.

Challenge 2: High Maintenance Effort

A gas engine is not a “set-and-forget” machine like a solar panel; it requires oil changes, spark plug replacements, and valve adjustments. Specialized expertise is needed for operation.

The PowerUP Solution: We take this complexity off your shoulders with our “Condition-Based Overhaul” approach. We replace parts based on actual condition, not just a calendar. Our cylinder heads or spark plugs are often designed to be more robust than standard components, maximizing uptime and lifespan.

Challenge 3: Dependence on Fuel Prices

A CHP plant needs fuel, and if gas prices rise, operating costs rise. This dependence on resources is a valid concern.

The PowerUP Solution: Efficiency is the best hedge against high prices. The more efficient the engine, the less gas you burn. Our upgrades get the maximum out of every cubic meter. Furthermore, we enable the switch to renewable energy sources like biogas or biomethane to decouple you from fossil markets entirely.

Challenge 4: Noise Emissions and Space Requirements

A running industrial engine generates noise and vibrations. In a purely industrial area, this is rarely a problem, but in residential buildings, hospitals, or mixed commercial areas, noise protection regulations are strict. Additionally, the system requires valuable space.

The PowerUP Solution: We offer maximum flexibility with our PUPGEN container solutions. These compact “plants in a box” can simply be placed outside on the premises. They are sound-insulated ex-works and solve the space and noise problem elegantly.

Comparison: CHP vs. Separate Generation

The direct comparison highlights why the benefits of combined heat and power outweigh the initial efforts. While separate generation wastes heat and relies on the grid, CHP optimizes every kilowatt-hour.

| Criterion | Cogeneration (CHP) | Separate Generation (Grid + Boiler) |

| Total Efficiency | Very High (85–95 %) | Medium to Low (40–60 %) |

| CO2 Emissions | Low | High (depending on grid mix) |

| Investment (CAPEX) | High | Low |

| Running Costs | Low (Self-production) | High (Grid purchase) |

| Maintenance | High (Engine) | Low (Boiler) |

| Resilience | High (Island mode) | Low (Grid dependent) |

Conclusion: Manage the Challenges with the Right Partner

The detailed look at the benefits combined heat and power offers shows: The strategic advantages—efficiency, cost reduction, and security—outweigh the cons, if the plant runs reliably.

The “downsides” are basically technical tasks that can be managed. And this is exactly where PowerUP comes in. We ensure that the cost factor “maintenance” becomes a competitive advantage. Through high-quality spare parts suitable for leading engine manufacturers and services like remote monitoring, we take the operational risk off you.

Optimize your cost structure now. To operate a CHP system efficiently, you need a partner who understands the engine inside out. Contact us for a non-binding consultation on alternative parts and upgrades.