Gas Engine Manufacturers: A Comprehensive Overview of Global Power Systems

The global landscape of power generation is heavily reliant on sophisticated industrial machinery. At the very heart of many on-site power solutions is the internal combustion engine, a prime mover increasingly optimized for gaseous fuels like natural gas.

This market is driven by a group of highly specialized engine manufacturers who are constantly advancing engine technology to meet demands for higher efficiency and lower emissions. In this comprehensive overview, we will explore the key global players, from industrial giants like Caterpillar and Cummins Inc. to the specialized gas engine companies that define the sector.

Gas Engine Manufacturers: A Comprehensive Overview of Global Power Systems

Differentiating Key Power Generation Technologies

Before diving into the specific engine manufacturers, it is essential to understand the technological landscape. The world of power generation includes several key technologies that are often confused but serve very different purposes.

Understanding the distinction between gas engines, diesel engines, and gas turbines is crucial for selecting the correct power systems for specific industrial applications.

Gas Engines vs. Diesel Engines and Gasoline Engines

The most common comparison is between different types of fuel engines. While gasoline engines are dominant in passenger cars, they lack the durability for continuous power generation.

The primary competition in on-site power solutions has long been between gas engines and diesel engines. Diesel engines, like those famously produced by Cummins Inc., offer high torque and reliability but face increasing scrutiny over their emissions (particularly NOx and particulates) and typically higher fuel consumption costs.

Gas engines, operating on natural gas, offer a cleaner combustion profile with significantly lower emissions, making them a preferred choice for sustainability initiatives and cogeneration applications.

Gas Engines vs. Gas Turbines

A frequent point of confusion in large-scale industrial applications is the difference between a reciprocating internal combustion engine (a gas engine) and a gas turbine. Gas turbines, often manufactured by industrial giants like Siemens, Rolls-Royce, or the General Electric Company, work more like a jet engine, using a continuous combustion process to spin a turbine.

They are exceptionally powerful and can scale to hundreds of megawatts, making them ideal for large, utility-scale power plants.

However, gas engines are generally more efficient at smaller scales (under 50MW), offer better flexibility (faster start-up times), and are far more effective for cogeneration (or CHP), as their high-temperature exhaust and cooling water are easier to harness for heat.

The Global Leaders: Key Gas Engine Manufacturers

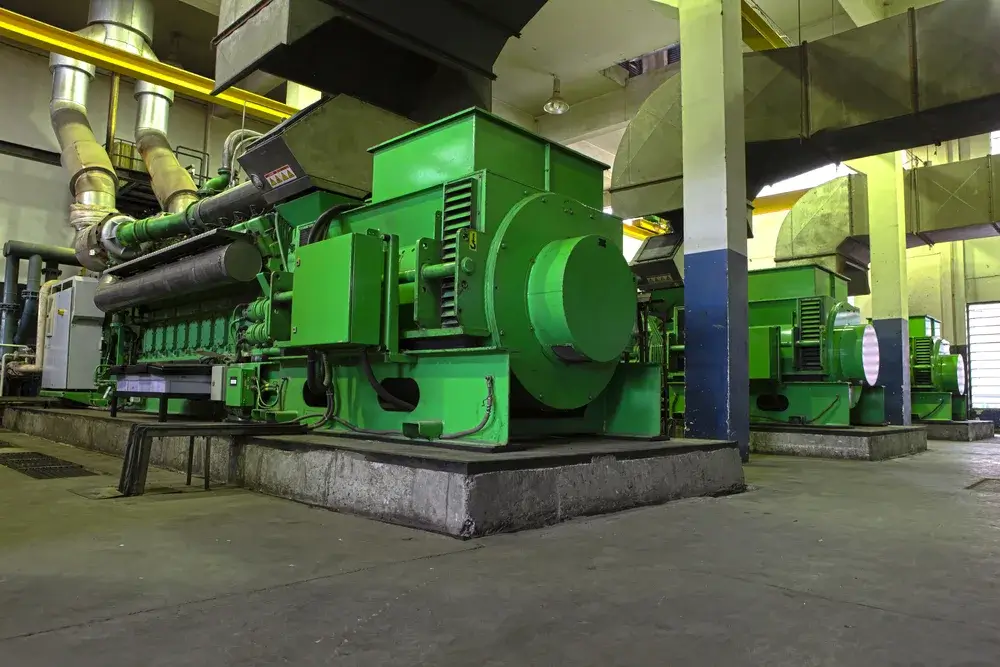

The market for high-capacity gas engines is dominated by a group of specialized, global engine manufacturers. These gas engine companies are the driving force behind the engine technology found in most power generation and cogeneration plants today.

While many companies produce industrial machinery, these leaders specialize in the design, production, and support of complex power systems built for maximum durability and performance.

INNIO (Jenbacher & Waukesha)

Prominently in the gas power sector is INNIO, a company that has become synonymous with gas engine innovation. INNIO’s portfolio includes two of the industry’s most respected names: Jenbacher and Waukesha.

- Jenbacher: Operating out of Austria, Jenbacher gas engines are a dominant force in the global cogeneration (CHP) market. They are renowned for their high efficiency and, crucially, their ability to run on a wide variety of fuels beyond just natural gas, including biogas and other challenging alternative fuels. This makes Jenbacher generator sets a top choice for industrial applications focused on sustainability.

- Waukesha: The Waukesha brand, with deep roots in the USA, is another critical part of the INNIO portfolio. Waukesha gas engines are known for their rugged durability and are particularly well-regarded in the oil and gas industry for their reliable on-site power systems.

Caterpillar (and MWM)

When it comes to heavy-duty industrial machinery, few names are more recognized than Caterpillar. While globally famous for its yellow construction equipment, Caterpillar is also a titan in the power generation market, offering a massive range of diesel engines and natural gas power systems.

- MWM: A key part of the Caterpillar Energy Solutions portfolio is MWM (Motoren-Werke Mannheim). With a rich German engineering heritage, MWM is a leading gas engine manufacturer in its own right, specializing in highly efficient gas engines and generator sets for cogeneration and greenhouse applications. The combination of Caterpillar’s global reach and MWM’s specialized engine technology makes them a formidable force in the gas power market.

Cummins Inc.

Another global power giant is Cummins Inc. Headquartered in the USA, Cummins is a premier engine manufacturer globally renowned for its high-performance diesel engines and power systems, which are used in trucks, buses, and even locomotives. Building on this deep internal combustion engine expertise, Cummins has also developed a robust portfolio of natural gas generator sets. Cummins power solutions are known for their durability and are used in a variety of industrial applications, from backup power to prime-load operation.

Rolls-Royce (Power Systems / mtu)

While most associated with aerospace, Rolls-Royce is a key player in on-site power generation through its Power Systems division (primarily the mtu brand). Rolls-Royce provides high-speed diesel engines and gas engine generator sets for a wide range of industrial applications, including data centers and mining. Their gas power solutions are engineered for high efficiency and reliability, serving a global market that demands premium engine technology and durability.

MAN Energy Solutions

MAN Energy Solutions, another German heavyweight, has a long history of building large-bore internal combustion engine systems. MAN is a leading engine manufacturer for marine propulsion, locomotives, and stationary power plants. Their gas engines are known for their enormous size and high power output, often used in large municipal cogeneration (CHP) plants, providing power and heat for entire cities. Their engine technology is focused on maximum efficiency at a massive scale.

Wärtsilä

Wärtsilä, based in Finland, is another global leader specializing in the large-bore gas engines market. Similar to MAN Energy Solutions, Wärtsilä focuses on the marine propulsion market and large, utility-scale flexible power plants. Their power systems are designed to respond rapidly to grid fluctuations, providing a stable gas power backbone. Wärtsilä‘s engine technology is a key component for grid stability and large-scale power generation projects worldwide.

Other Key Gas Engine Companies and Industrial Players

Beyond the dominant manufacturers who specialize heavily in large generator sets, massive industrial conglomerates also serve the global market. These companies often produce gas engines as part of a much broader portfolio, leveraging their vast engineering expertise from other sectors.

Asian Industrial Giants

Several major engine manufacturers are based in Asia, leveraging their extensive experience in shipbuilding, construction equipment, and heavy industrial machinery to compete in the power systems market.

- Mitsubishi Heavy Industries (MHI): A diversified Japanese giant, MHI produces a wide range of power systems, including highly efficient gas engines and gas turbines, serving global industrial applications.

- Hyundai Heavy Industries (HHI): While often known for shipbuilding, Hyundai also manufactures medium-speed gas engines and diesel engines for stationary power generation and marine applications.

- Kawasaki Heavy Industries: Another key Japanese player, Kawasaki Heavy Industries produces gas engines and gas turbines, often recognized for their advanced engine technology and emissions controls.

- Yanmar: Yanmar is a well-known manufacturer specializing in smaller to medium-sized gas engines and diesel engines, particularly for marine use, construction equipment, and on-site cogeneration systems.

Other European and American Specialists

Finally, it is important to mention other industrial titans that, while perhaps more focused on gas turbines today, have fundamentally shaped the power generation landscape.

- Siemens: While the Siemens energy division (now Siemens Energy) is a dominant force in large gas turbines and grid-level power solutions, its engineering legacy is deeply rooted in industrial machinery and energy.

- General Electric Company: The General Electric Company (GE) is a foundational name in power generation. GE was the former parent company of INNIO (before its sale) and continues to be a dominant force in the energy sector, particularly with its own large-scale gas turbines and grid power solutions.

Driving Forces: Advancements in Engine Technology

This massive global market is not static. The intense competition between these engine manufacturers is driving significant advancements in engine technology.

This innovation is not optional, it is a response to powerful market and regulatory pressures that are reshaping the entire power generation industry.

The Push for Sustainability and Lower Emissions

The single most significant driver is the global push for sustainability. Governments and corporations worldwide are implementing strict initiatives to reduce emissions (particularly NOx, CO2, and methane). This has forced advancements in engine technology focused on clean combustion. Gas engines, which burn natural gas, are inherently cleaner than diesel engines in terms of particulates and SOx.

However, manufacturers are in a constant race to improve after-treatment systems and combustion efficiency to meet these ever-tightening environmental standards, positioning gas power as a viable bridge technology.

Focus on Fuel Consumption, Durability, and Power Output

Beyond emissions, the primary competitive battleground for engine manufacturers is operational economics. For an operator, the three most important metrics are fuel consumption, durability, and power output.

Customers demand generator sets that produce more megawatts (power output) while burning less fuel (fuel consumption). Above all, they demand extreme durability—long service intervals and a high resistance to wear.

These economic drivers force manufacturers to invest heavily in materials science, advanced engine technology, and robust controls to ensure their power systems are not just clean, but profitable.

Your Expert Partner in a Multi-Brand Gas Engine World

The landscape of gas engine manufacturers is complex. An operator may run a mixed fleet, with gas engines from INNIO Jenbacher at one site and Caterpillar MWM units at another.

This multi-brand environment, featuring dozens of gas engine companies from Cummins Inc. to MAN Energy Solutions, creates significant challenges for maintenance and optimization.

This is precisely where PowerUP provides value. We are not on the list of engine manufacturers, we are the leading independent specialist focused on servicing and optimizing them. Our engine technology and expertise are laser-focused on the industry’s most critical power systems, especially suitable for INNIO Jenbacher and Caterpillar MWM generator sets.

Technology is our drive, efficiency our focus. We provide the advanced power solutions, high-durability spare parts, and expert service to maximize the power output and sustainability of your assets—regardless of the original manufacturer.