Powering Progress – A Comprehensive Guide to Jenbacher® Gas Engine Series

Jenbacher gas engines have formed the backbone of countless energy facilities worldwide for decades. Whether powering a remote biogas farm in the countryside or serving as the heartbeat of a modern cogeneration facility for industrial manufacturing: These machines stand for innovation and performance.

But the portfolio is vast. From the compact entry-level model to the massive power plant engine, the various series (Jenbacher Type) cover a spectrum from 250 kW to over 10 MW.

The Conflict: With such a broad range, which series is the right one for your specific project? And more importantly: How do you ensure that this multi-million dollar investment remains profitable after years of operation?

The Solution: In this comprehensive guide, we provide an overview of the Jenbacher gas engine series. We show where their strengths lie and how we at PowerUP, as an independent partner, ensure with spare parts and services that your energy solutions remain efficient permanently.

Overview: Which Engine for Which Application?

Choosing the right engine depends on more than just pure energy demand. Factors such as available gas quality (natural gas vs. biogas), the desired type of power generation, and the need for heat extraction (CHP) play a decisive role.

While high efficiency is often the most important criterion for Independent Power Producers (IPPs), operators of biogas plants prioritize robustness against fluctuating gas compositions. A deeper understanding of the technology helps here—you can find more on this in our article on how do Jenbacher engines work.

Jenbacher® Type 2: Compact Power for Biogas and Sewage Gas

The Jenbacher Type 2 (e.g., J208) marks the entry into the world of Jenbacher engines. With a power range of approx. 250 to 350 kW, it is the smallest representative, but by no means to be underestimated. Its construction is designed for maximum robustness. Since no heavy lifting gear is required for maintenance, it is perfectly suited for decentralized onsite locations.

Applications: It is frequently found in smaller biogas plants, on landfills using landfill gas, or in wastewater treatment plants running on sewage gas. It handles renewable gases with lower methane content excellently.

The PowerUP Advantage: Wear is a major issue with aggressive gases. We offer spark plugs and filters developed suitable for the Jenbacher Type 2, designed to achieve long service lives even under difficult conditions.

Jenbacher® Type 3: The Global Workhorse

If there is an engine that has shaped the reputation of the INNIO Jenbacher brand as a synonym for reliability, it is the Series 3 (e.g., J312, J316, J320). With an output of 500 to 1,100 kW, it is the “all-rounder” in the portfolio.

Applications: This engine is the workhorse of agriculture and green energy. Many of our customers, such as farmers with their own biogas production, swear by the Type 3. It is forgiving, maintenance-friendly, and offers an excellent balance of performance and technical maturity.

The PowerUP Advantage: Since the Type 3 is so widespread, we have optimized our stock perfectly for it. Whether cylinder head revision or a complete shortblock exchange: We ensure that your “long-distance runner” takes no unnecessary breaks. Our upgrades aim to further increase the efficiency of these proven machines.

The Ultimate Guide to Jenbacher® Gas Engines

Discover everything about INNIO Jenbacher engines: From Type 2 to Type 9, biogas, MyPlant, and cogeneration. Maximize your power generation with PowerUP.

Jenbacher® Type 4: Efficiency meets Performance

In the power range of approx. 800 to 1,500 kW, the Jenbacher Type 4 (e.g., J412, J416, J420) sets standards in terms of efficiency. This series was consistently trimmed for high efficiency and features state-of-the-art 4-valve technology.

Applications: The Type 4 is popular in applications where every percentage point of efficiency is worth cash. Operators of greenhouses who use electricity and CO2 for fertilization, or industrial companies utilizing Combined Heat and Power (CHP), frequently rely on this series. It is a high-tech aggregate that rewards precise maintenance.

The PowerUP Advantage: High efficiency demands precision. Our spare parts for the Type 4 (such as cylinder liners and piston rings) are manufactured to safely master high combustion pressures and keep efficiency stable over the entire life cycle.

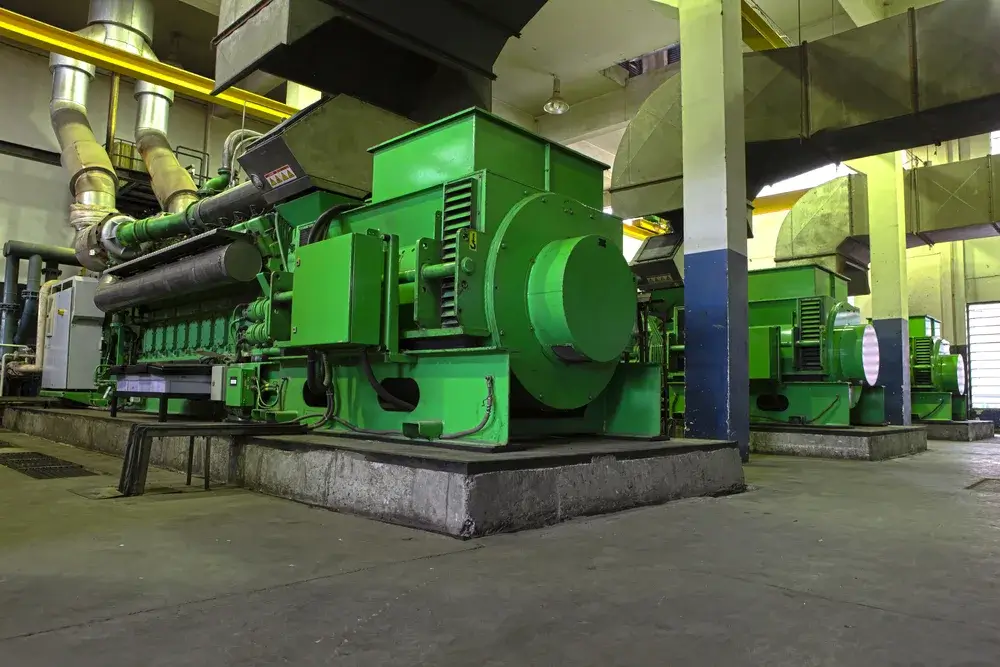

Jenbacher® Type 6: The Powerhouse for Major Projects

Here we move into the league of large engines (1.8 to 4.5 MW). The Jenbacher Type 6 (e.g., J612, J620, J624) is massive, powerful, and designed for extreme continuous load. The J624 was also the world’s first 24-cylinder gas engine.

Applications: This series is the first choice for Independent Power Producers (IPP) and large municipal utilities. It is critical for data centers needing reliable backup power and microgrid stabilization. For operators in this segment, every day of downtime means massive losses. The engine must run—stably and predictably.

The PowerUP Advantage: We know that availability is everything for IPPs. That’s why we offer not only individual parts for the Type 6 but also fast solutions like exchange shortblocks or complete generator set revisions. Our goal is to reduce your downtime to an absolute minimum.

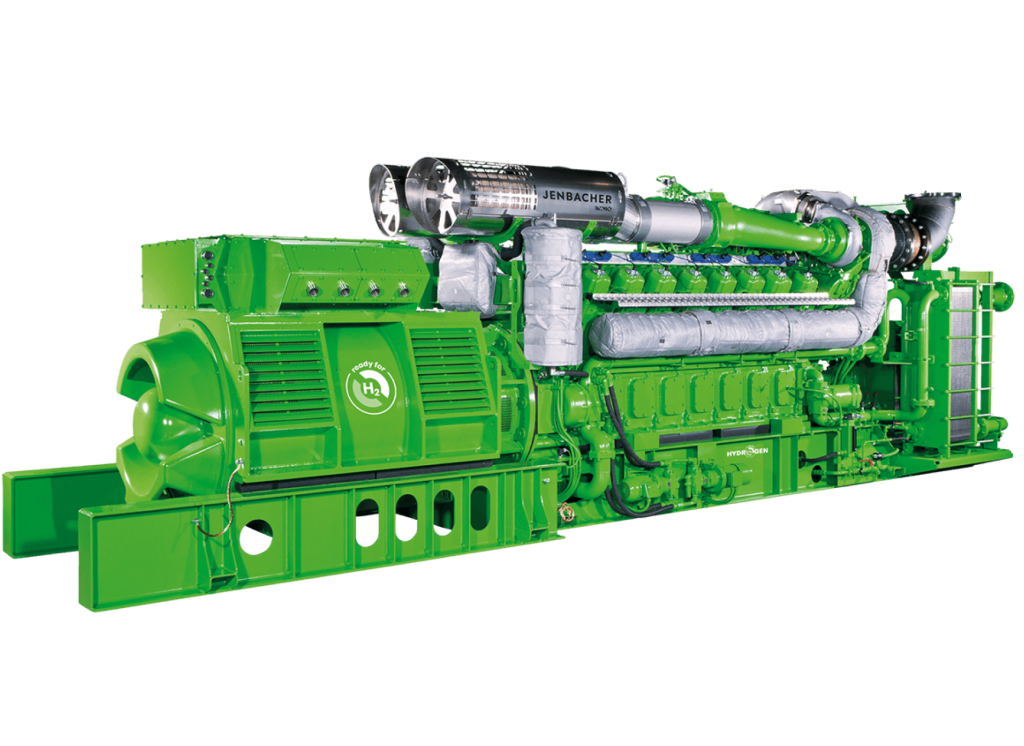

Jenbacher® Type 9 (J920 FleXtra): The New Dimension

The Type 9 (J920 FleXtra) is the technological flagship and ventures into areas with over 10 MW output that could previously only be covered with multiple engines. With an electrical efficiency of over 50%, it belongs to the most efficient gas engines worldwide.

Applications: Large energy projects, grid stabilization, and peak load power plants. Due to its two-stage turbocharging and flexible design, it is predestined for the challenges of the modern energy transition towards Net Zero.

The PowerUP Advantage: Even for giants like the J920, independent support matters. While major overhauls are often OEM-bound, we support operators with ancillary components, independent consulting, and remote monitoring integration to ensure your grid stabilization assets perform optimally within the larger fleet.

Extending Life Cycle: Service for All Series

Whether you operate a compact Type 2 or a mighty Type 6—every engine eventually reaches the end of its first life cycle. But that doesn’t have to be the end of the plant.

A general overhaul (rebuild) is often the more economical and sustainable alternative to buying new. In our article “Revitalizing Power”, we explain in detail how we give engines of all series a second life through professional overhaul. We know the specific weaknesses and strengths of each series and adapt our service exactly to them.

Innovation Needs the Right Partner

Jenbacher technology is our drive, efficiency our focus. The variety of Jenbacher gas engine series offers the right solution for almost every requirement. But to operate this technology profitably for over 60,000 operating hours and more, you need a partner who delivers not just parts, but solutions.

We at PowerUP see ourselves as this partner. Independent, flexible, and with a clear goal: To secure the success of your power generation.

- Bespoke Parts: For Jenbacher Type 2 to Type 6.

- Availability: So your engine runs when it matters.

- Expertise: From maintenance to upgrades.

Let’s find out together how we can optimize the performance of your specific series.