The construction of energy plants with gas engine drive

The Construction of energy plants with gas engine drive is a multi-faceted process that transforms a strategic concept into a high-performance, revenue-generating asset. While the gas engine is the heart of the system, its successful implementation depends on a complex ecosystem of engineering, planning, and logistics.

For Independent Power Producers (IPPs), developers, and large-scale facility managers, understanding this process is critical for ensuring a project’s success. Technology is our drive, efficiency our focus.

This article provides a comprehensive guide through the four essential phases of bringing Plants With Gas Engine Drive online.

Phase 1: Strategic Planning and Feasibility Study

Before any ground is broken, the viability of the entire project is determined in the strategic planning phase. This is the most critical step for any IPP to secure financing and justify the investment. This phase involves:

- Site Selection and Permitting: The location must have access to a reliable fuel source (like a natural gas pipeline or biogas facility) and efficient access to the electrical grid. This stage includes comprehensive environmental assessments and securing all local regulatory permits.

- Fuel Strategy and Grid Connection: This involves securing long-term fuel supply contracts. Crucially for an IPP, it also means negotiating Power Purchase Agreements (PPAs) or grid connection terms to guarantee a stable revenue stream for the energy produced.

- Economic Modeling (CAPEX vs. OPEX): This is where the project’s financial feasibility is proven. It involves a detailed analysis of Capital Expenditure (CAPEX)—the initial cost of the Construction Of Energy Plants—versus the long-term Operational Expenditure (OPEX), which includes fuel, maintenance, and staffing.

Phase 2: Detailed Engineering and Design of Plants With Gas Engine Drive

Once the project is deemed feasible, the detailed engineering phase translates the financial models into technical blueprints. This stage defines the exact specification of all gas engine components and supporting infrastructure.

- Core Component Selection: This is the selection of the gas engine and generator set (genset) itself. Engineers choose the appropriate MW-class engine (e.g., from leading manufacturers like INNIO Jenbacher or MWM, for which PowerUP specializes in service) to meet the required power output.

- Designing the “Balance of Plant” (BOP): This industry term refers to all the auxiliary systems required to support the engine. This includes the cooling systems (radiators, cooling towers), the complete exhaust gas system (including emissions control like SCR catalysts), and, if applicable, the heat recovery systems for Combined Heat and Power (CHP) applications.

- Control Systems and Plant Automation: Modern Plants With Gas Engine Drive are highly automated. This part of the design involves specifying the master control system (like PowerUP’s AORA or EDI solutions), which manages everything from engine parameters to grid synchronization and remote monitoring.

The construction of energy plants with gas engine drive

A comprehensive guide to the Construction of energy plants with gas engine drive. We explore the 4 key phases: from strategic planning, feasibility, and PPA negotiation to engineering, physical construction, and commissioning.

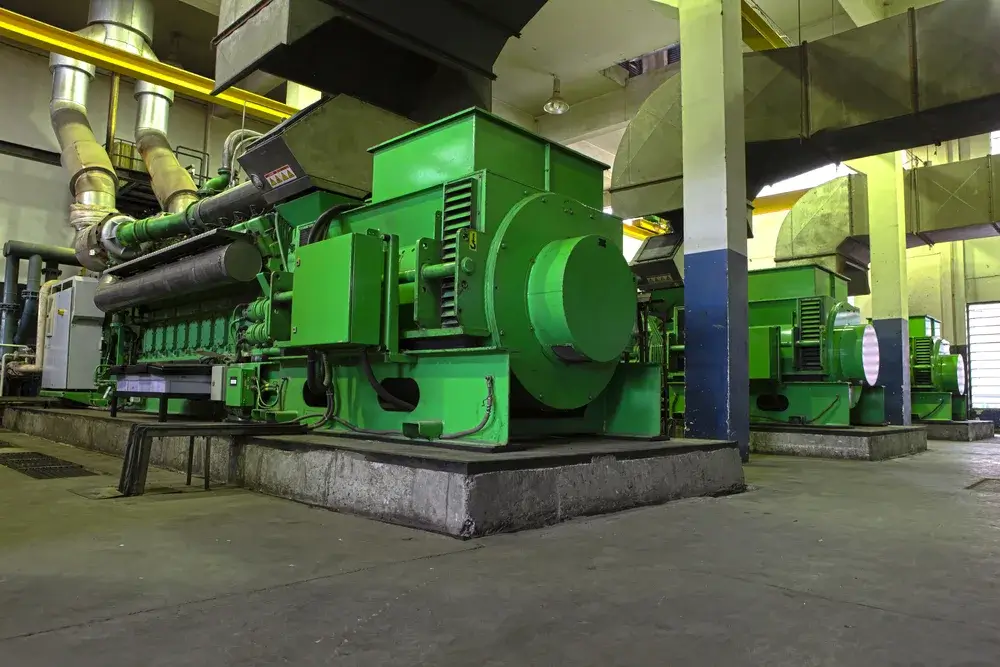

Phase 3: The Physical Construction Of Energy Plants

With the designs approved, the physical Construction Of Energy Plants begins. This phase is a carefully orchestrated logistical operation involving multiple contractors.

- Civil Works and Foundations: This includes preparing the site and pouring the massive, reinforced concrete foundation. This foundation is a critical engineering component designed to absorb the immense vibration of the heavy-duty engine operating 24/7.

- Mechanical and Electrical Installation: This is the “setting” of the engine. The multi-ton genset is precisely lifted and mounted onto the foundation. This is followed by the installation of all auxiliary systems, including miles of piping for fuel, lubrication, and cooling, as well as the high-voltage busbars and switchgear.

- Integration of Auxiliary and Safety Systems: This final construction step involves installing the “skin” of the plant—the engine housing or container—along with essential fire suppression, ventilation, and fuel-handling systems to ensure safe engine operation.

Phase 4: Commissioning, Testing, and Handover

The final phase transforms the completed construction site into a verified, operational power plant. Commissioning is a meticulous process to ensure every one of the thousands of components works in perfect sync.

- System Checks and First Firing: Engineers first conduct “cold commissioning” to test all electrical circuits and fluid systems without starting the engine. This is followed by the “hot commissioning” or “First Firing”, the milestone moment when the gas engine is started for the very first time.

- Performance Trials and Grid Synchronization: The engine is gradually brought up to full load. Technicians conduct performance trials to verify that the plant meets its designed power output and engine efficiency. Once proven, it is synchronized with the electrical grid.

- Final Handover and Start of Operation: After the plant successfully passes all performance and safety tests, the construction and engineering teams officially hand the keys over to the operator (the IPP). The asset is now ready to begin its decades-long service life.

Combined Heat and Power: Benefits and Challenges in an Honest Check

Is CHP worth it? We analyze 8 benefits (efficiency, costs) and 4 challenges (maintenance, noise) and how PowerUP solutions help you master them.

Beyond Construction: PowerUP as Your Lifecycle Partner

The Construction of energy plants with gas engine drive is only the beginning of the journey. The “Biggest Pain” for any operator is not the construction, but the threat of unplanned downtime, which instantly stops revenue. Once the construction crews leave, the real challenge of maximizing reliability and engine efficiency for the next 60,000 operating hours begins.

This is where PowerUP becomes your essential partner. We are not a construction company; we are the specialists who ensure your asset remains profitable. Technology is our drive, efficiency our focus. We provide the expert Field Service, advanced gas engine maintenance parts, and sophisticated control upgrades to reduce your OPEX and eliminate downtime. While others build the plant, PowerUP ensures it delivers maximum performance for its entire lifespan.