Gas engines – a comprehensive insight

In the modern world of propulsion technology, gas engines continue to play a significant role. These specialized engines, which utilize gas as a fuel, offer an environmentally friendly and efficient alternative to traditional combustion engines. From small, portable units to large, industrial installations, gas engines are widely used in various applications and industries.

This article provides a comprehensive insight into the functioning, advantages, and applications of gas engines, highlighting their increasing significance in today’s energy landscape.

Who invented the gas engine?

The gas engine, often referred to as a reciprocating engine, has undergone significant development over the years. Although it is difficult to attribute the exact invention of this motor to a single individual, as various inventors in different regions were working on similar concepts, there are certain key figures and milestones that should be highlighted.

The first beginnings of the gas engine can be traced back to the 19th century. Various inventors and engineers conducted experiments with gases, primarily with the aim of finding an alternative source of propulsion to the steam engines that were dominating at the time. The use of gas as a fuel was particularly attractive due to its reputation as a cleaner and more efficient energy source, especially when compared to solid fuels like coal.

One of the earliest functional models of such an engine was developed in the 1860s. The displacement played a crucial role as it defined the volume in which the gas was ignited to generate mechanical work. Although some of the early models of gas engines had significant technical flaws, this did not deter numerous engineers from making further advancements and improvements.

Throughout the years, inventors from various countries have made significant contributions to the development of the gas engine. These advancements and innovations have transformed the gas engine into what it is today: a dependable and efficient source of energy that is used in a wide range of applications.

Who was Carl Benz?

Carl Benz, born on November 25, 1844 in Mühlburg, which is now a district of Karlsruhe, was an exceptional German engineer and inventor.

How does a gas engine work?

The gas engine, like many other combustion engines, converts chemical energy into mechanical energy, which is then used as a driving force for various applications. The basic operation of the gas engine is based on a continuous cycle of intake, compression, ignition, and exhaust.

At the start of the cycle, a gas-air mixture is drawn into the engine’s combustion chamber. This process is achieved through mixture formation, where the gas is mixed with air in a specific ratio. After the mixture is drawn in, it undergoes compression in the combustion chamber. The compression raises the temperature and pressure of the mixture, preparing it for subsequent ignition.

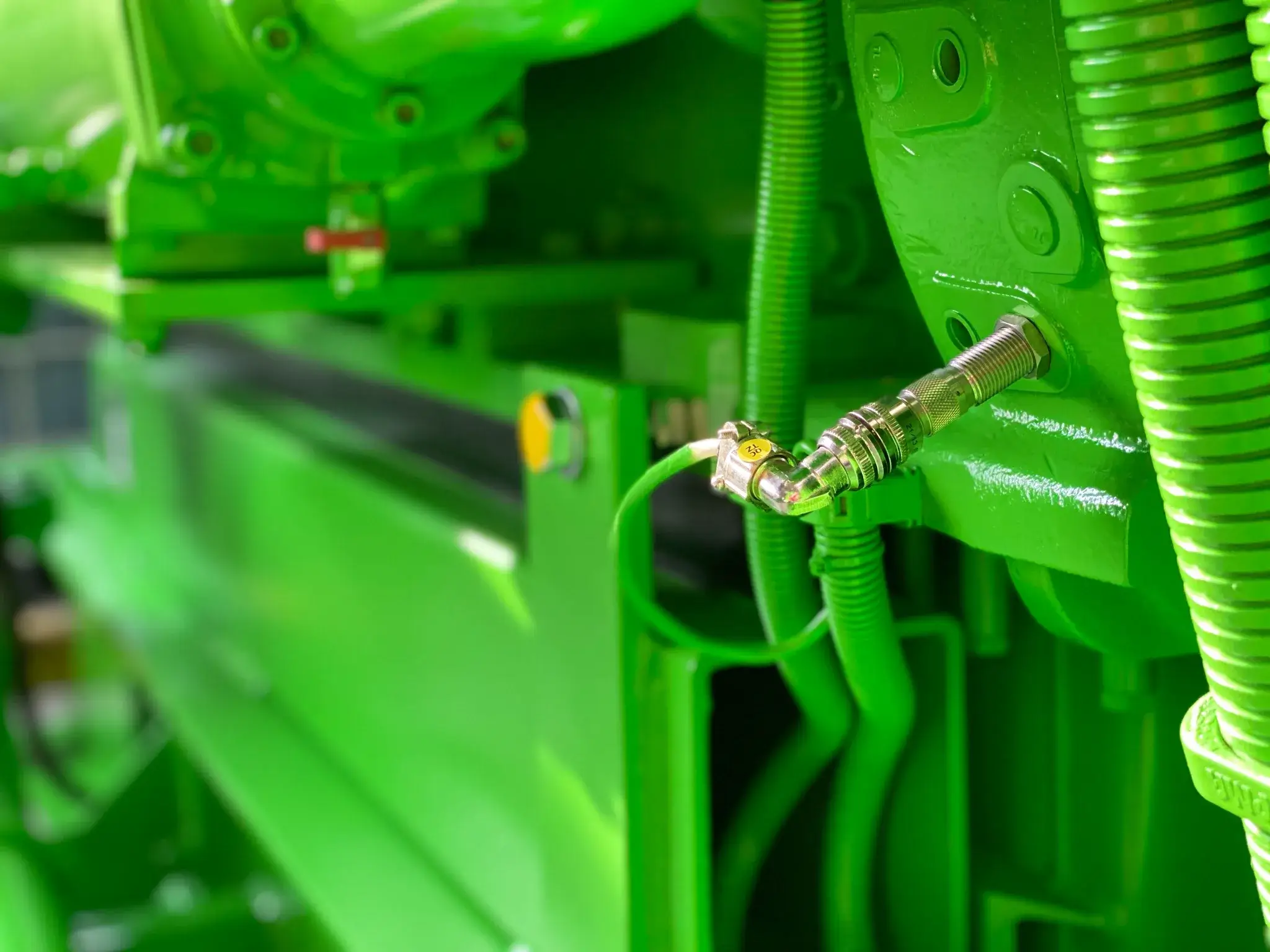

The ignition of the compressed mixture can occur in two different ways: through spark ignition or self-ignition. In a gas engine, spark ignition is typically used, where a spark plug generates a spark to ignite the mixture. Once ignited, the mixture burns, releasing energy. This energy drives the piston, which in turn sets the engine’s crankshaft in motion.

The final stage of the cycle is the expulsion of the burned gases from the combustion chamber. Once the burned gases have been expelled, the cycle begins anew.

The ignition is the crucial component of the gas engine. It is of paramount importance that the ignition occurs at the correct moment and with the appropriate energy level. This ensures that the engine operates efficiently and effectively extracts the maximum energy from the gas-air mixture.

It is also important to mention that there are different types of gas engines that employ various ignition systems and mixture formation methods. For instance, some utilize direct injection, while others rely on mixture formation in the intake tract.

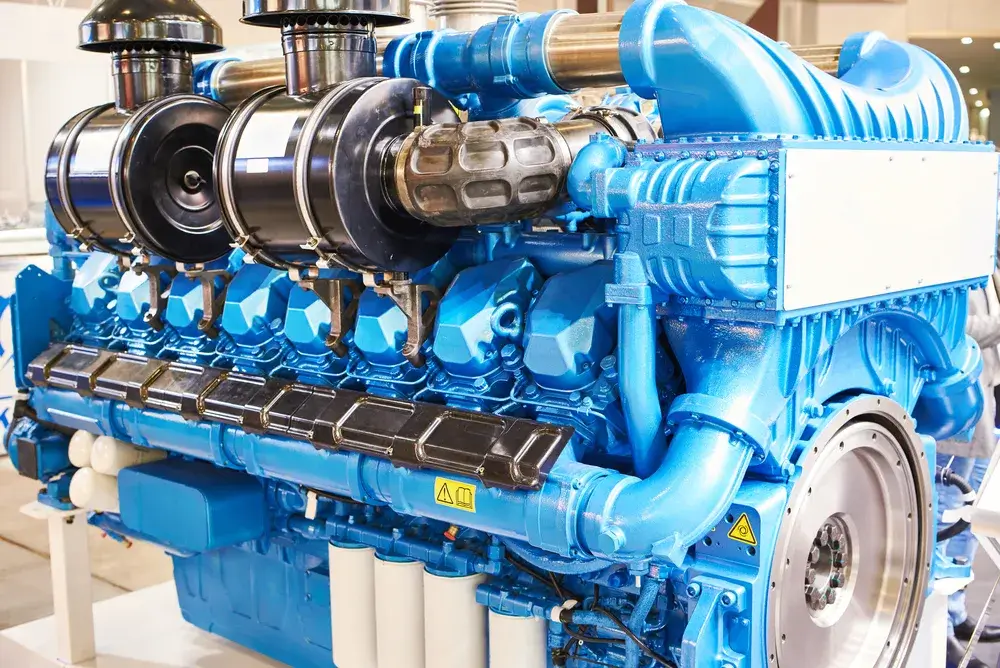

Comparison between Gas Engines and Other Engines

In order to better understand the differences and similarities between gas engines and other types of engines, let’s take a closer look at their respective modes of operation, advantages, and challenges.

- Gas engine: As mentioned earlier, the gas engine utilizes various types of gases as fuel. It predominantly employs spark ignition, where a spark plug ignites the gas-air mixture. Gas engines are renowned for their low emission levels and often provide higher efficiencies, particularly when enhanced with modern technologies like turbochargers.

- Diesel engines: Diesel engines use diesel fuel and operate on the principle of compression ignition. This means that the diesel fuel is ignited by the high pressure created during the compression phase, without the need for an external ignition source. Diesel engines are generally known for their robustness and often provide higher fuel efficiency compared to gasoline engines. However, they tend to emit higher levels of nitrogen oxides and particulate matter.

- Petrol engine: This is the most widely used type of engine for passenger cars and is based on gasoline engines. Similar to the gas engine, it uses spark ignition through a spark plug. Compared to diesel engines, petrol engines are generally quieter and emit fewer pollutants, but they do tend to consume more fuel and have a lower efficiency.

The decision between a gas engine and other types of engines often depends on various factors, including specific application requirements, fuel costs, environmental regulations, and the availability of fuel infrastructure

While gas engines can dominate in certain areas, such as power generation and industrial applications, diesel and petrol engines have their own specific niches, particularly in the transportation sector.

What types of gas engines are there?

Gas engines (German: Gasmotoren) are available in a wide variety, almost as extensive as the various types of gases themselves. The differences can be categorized based on the type of gas used, specific applications, or technological variations.

Based on the type of fuel used

- Biogas engines: These engines utilize biogas as a fuel source that is produced through the anaerobic decomposition of organic materials, often found in biogas plants.

- Methane Gas Engines: They utilize methane, which is often a primary component of natural gas.

- Engines for landfill gas: Landfill gas is produced from the decomposition of organic waste in landfill sites.

- Engines for wood gas: Wood gas is generated through the process of gasification, which involves converting wood or other biomass into a combustible gas.

- Liquefied petroleum gas engines: These engines utilize liquid fuels like liquefied petroleum gas (such as propane or butane) as their source of fuel.

- Low-gas engines: Utilize weak gases that are produced, for example, in coal gasification

Based on the application

Stationary gas engines: These engines are used in stationary facilities, often in power generation or as backup generators.

Blockheizkraftwerke (BHKW): These gas engines are integrated into CHP systems that utilize cogeneration to simultaneously generate electricity and heat, thereby achieving higher efficiencies.

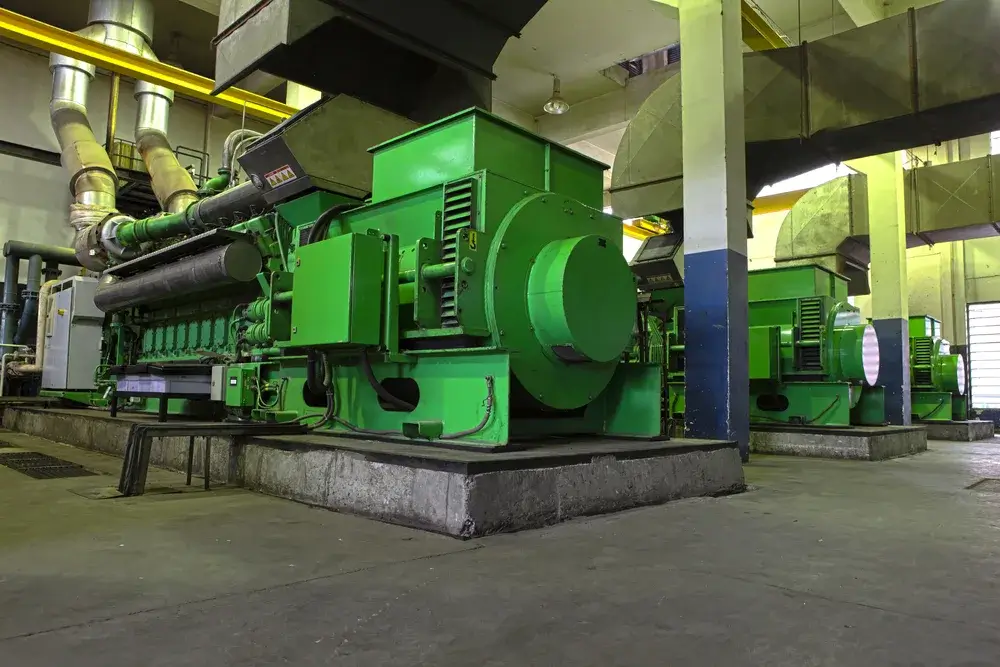

Stationary gas engines

Stationary gas engines are specifically designed for stationary facilities and applications where mobility is not essential. They play a vital role in various industries and applications that require a dependable and uninterrupted energy supply.

Power generation

One of the most common applications for stationary motors is power generation. In this process, the gas is combusted to power a generator that produces electricity.

This can be done in larger power plants or in smaller units such as emergency generators, which are used to bridge power outages or provide electricity in remote areas.

Cogeneration plants (CHP)

Stationary gas engines are commonly used in combined heat and power plants. These systems utilize cogeneration to generate both electricity and heat, leading to increased efficiencies.

In other words, while the electric energy is being generated, the heat that would typically be lost as waste is instead utilized for heating or other purposes.

Drive of industrial machines

In certain industrial applications where constant power and high torque are necessary, stationary gas engines are utilized as a source of propulsion for machines.

Gas engine and combined heat and power plant – what are the benefits?

A combined heat and power plant (CHP) combines the production of electrical power and usable heat in a single facility, typically powered by a gas engine. This integrated approach to energy production offers a variety of advantages.

Higher efficiencies

By combining electricity generation and heat recovery in a CHP (Combined Heat and Power) system, a significantly higher efficiency can be achieved compared to separate production methods. This means that less fuel is consumed to generate the same amount of energy.

Optimal utilization of biogas

CHP plants are especially effective when operated with biogas from biogas plants. This allows for the sustainable utilization of waste products while simultaneously reducing greenhouse gas emissions.

Cogeneration

The principle of cogeneration in CHPs ensures that the waste heat generated during energy generation is not wasted but instead utilized for heating purposes or industrial processes. This significantly boosts the overall efficiency of the system.

Reduced emissions

Thanks to their efficient combustion and the utilization of cleaner fuels like methane or biogas, gas engines in combined heat and power (CHP) plants generate fewer harmful emissions compared to other fuel sources.

Flexibility and reliability

Combined Heat and Power (CHP) plants, particularly those equipped with gas engines, have the ability to respond flexibly to fluctuations in electricity demand. Moreover, they provide a dependable source of energy during power outages, especially when paired with backup generators.

Economy

Due to the dual production of heat and electricity, Combined Heat and Power (CHP) systems can offer greater economic benefits, particularly when both energy forms can be utilized locally. This can result in reduced operational expenses and enhanced profitability for investments in CHP systems.

How does the efficiency of a gas engine compare to that of other engines?

The efficiency of an engine indicates the proportion of the energy introduced into the fuel that is converted into usable mechanical work. Comparing the efficiency of gas engines with other types of engines is crucial for understanding their efficiency and cost-effectiveness.

Gas engine

Gas engines, particularly those that utilize advanced technologies like turbochargers, have the potential to achieve higher levels of efficiency, particularly within combined heat and power (CHP) systems such as cogeneration plants.

The clean combustion of gas, especially methane and biogas, results in a more efficient conversion of energy and reduced heat losses in the combustion chamber. The utilization of specialized technologies and components, such as those offered by companies like PowerUP, can further enhance the efficiency of gas engines.

Diesel engines

Diesel engines are renowned for their high efficiency. Their self-ignition capability and the ability to operate at higher pressures often result in superior efficiency compared to gasoline engines.

However, the use of diesel fuel, which is a liquid fuel, may have less favorable implications in terms of emissions and environmental impact when compared to gas.

Gasoline engine

Petrol engines, which are based on gasoline engines, generally have a lower efficiency compared to diesel engines. This is partially due to their spark ignition system and the resulting temperature and pressure limitations.

However, advanced technologies such as direct injection and precise fuel-air mixture formation can significantly improve the efficiency of gasoline engines.

It is important to emphasize that efficiency is not the only criterion for selecting an engine. Factors such as fuel costs, availability of spare parts, environmental regulations, and specific application requirements also play a crucial role in the decision-making process.

Who are the largest manufacturers of gas engines?

The production of gas engines is a highly specialized field in which some companies have achieved a dominant position due to their technical expertise, quality, and innovation.

MAN

MAN is a globally recognized company in the field of engine manufacturing. It has a longstanding tradition in the development and production of combustion engines and is also active in the gas engine industry. MAN gas engines are renowned for their reliability and efficiency.

INNIO Jenbacher

INNIO Jenbacher has established itself as one of the leading manufacturers of gas engines. Their engines are especially sought-after in combined heat and power (CHP) plants and other stationary applications.

MWM®

MWM® stands for Motoren-Werke Mannheim and is another major player in the field of gas engines. The company offers a wide range of gas engines that can be operated with both methane and biogas.

Caterpillar

As one of the largest manufacturers of construction equipment worldwide, Caterpillar has also significantly expanded its presence in the gas engine segment, especially through the acquisition of MWM.

Caterpillar gas engines are renowned for their durable construction and high performance, making them suitable for various industries, ranging from power generation to shipping. The company places a strong emphasis on sustainability and offers engines that can be operated using renewable gases.

There are numerous other manufacturers of gas engines worldwide. Some specialize in specific fuels, such as liquefied petroleum gas (LPG), landfill gas, or wood gas. Others concentrate on particular power ranges or applications, such as power generation or stationary applications.

Gas Engine Manufacturers — an Overview

As an alternative to traditional diesel engines, gas engines offer a clean and effective solution for various industrial applications. Learn more about the big players in gas engine manufacturing!

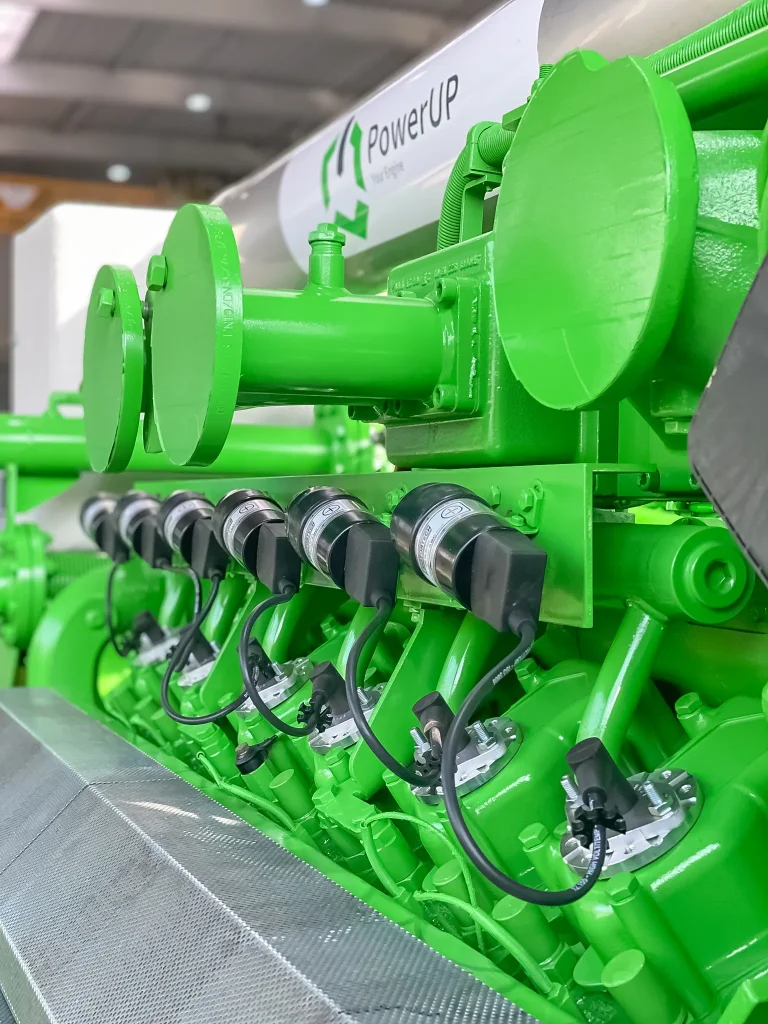

Future-proof gas engines with PowerUP

At PowerUP, we specialize in providing customized gas engine solutions. These include gas engine upgrades, complete overhaul of gas engines and gas engine repairs. As a manufacturer-independent service provider, we offer a wide range of gas engine spare parts and services for different brands of gas engines – such as INNIO, MWM®, and Caterpillar.

Our portfolio includes not only the swift and expert repair of engines, but also services such as performance-enhancing upgrades and condition overhauls to prolong the lifespan of your engines. Our expertise across various brands enables us to offer a high degree of flexibility and adaptability to meet our customers’ specific requirements.

Furthermore, we sell refurbished gas engines, provide replacement engines during overhauls or other, and we offer gas engines for rent and our complete gas engine container solution PUPGEN. Learn more about the advantages to be with PowerUP and get in contact with our specialist regarding your needs.