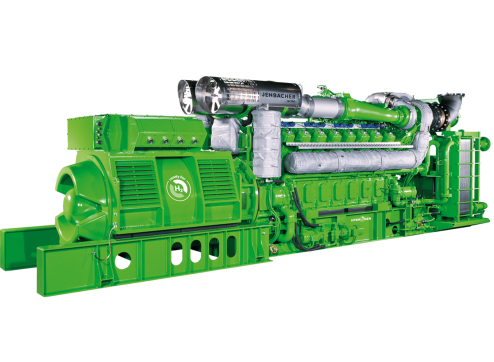

Inside the Jenbacher® Type 6 Series – The Powerhouse for Major Projects

When energy demand is measured in megawatts, standard technology is no longer enough. This is where the Jenbacher Type 6 series enters the stage. With a power range of 1.8 to 4.5 MW, this series is the backbone of large power plants worldwide. It combines massive force with an efficiency otherwise only known from smaller, high-performance engines.

For Independent Power Producers (IPP) and operators of large industrial facilities, the Type 6 is often the first choice. But with great power comes great responsibility—in maintenance and operation.

In this article, we illuminate the engine technology behind the models J612 to J624 and show how you can secure the availability of these giants with spare parts and services from PowerUP.

The League of Heavyweights: Models and Performance

The Jenbacher Type 6 series was developed for applications where constant, continuous output and high efficiency are crucial. It is technologically designed to convert large amounts of fuel (mostly natural gas, but also biogas) into electricity as efficiently as possible.

The family includes:

- J612: The entry into the V12 class (approx. 1,800–2,000 kW).

- J616: The V16 engine (approx. 2,400–2,700 kW).

- J620: The worldwide bestseller in this class (V20, approx. 3,000–3,500 kW).

- J624: The flagship and the world’s first 24-cylinder gas engine (up to 4,500 kW).

A look at the history of INNIO Jenbacher shows that especially the J624 with its innovative 2-stage turbocharging marked a milestone in engine development.

Technology in Detail: Pre-Chamber and Efficiency

What technically distinguishes a Jenbacher Type 6 from its smaller brothers? While the basic principle of Jenbacher gas engines remains the same (4-stroke principle), the Type 6 uses special technologies for the large series.

The Pre-Combustion Chamber

To ignite a lean gas-air mixture quickly and cleanly in the huge cylinders (bore approx. 190 mm), a simple spark plug is often not enough. The Type 6 therefore often uses the pre-chamber principle: A small amount of gas is ignited in a separate chamber. The “torches of fire” shooting out of it then ignite the main mixture in the cylinder extremely quickly and evenly. The result: Maximum efficiency and low emissions.

The Turbocharger as a Power Source

With large engines, the air requirement is enormous. High-performance turbochargers ensure that the cylinder filling is optimal even at full load. The J624 even uses 2-stage charging, which ensures stable performance, especially in hot environments or at high altitudes.

Applications: Where the Type 6 Dominates

The Jenbacher Type 6 is not an engine for the hobby basement. It is an industrial tool designed for scenarios where reliability and scale are non-negotiable.

Independent Power Producers (IPP)

For IPPs, flexibility and uptime are the currency of success. In a volatile energy market, every kilowatt-hour counts. Operators often deploy entire batteries of J620 engines to create flexible power plants capable of reacting instantly to electricity price fluctuations or stabilizing microgrids. The Type 6’s ability to ramp up quickly makes it an ideal asset for peak-shaving and balancing the intermittency of renewables.

District Heating and CHP

The Type 6 is a perfect match for large-scale Combined Heat and Power (CHP) plants due to its immense thermal output. By recovering heat from the engine jacket, oil, and exhaust gas, these engines can supply entire city districts or industrial parks with hot water and steam.

This cogeneration capability drives the total efficiency of the plant to over 90%, transforming waste heat into a valuable revenue stream.

Commercial Horticulture (Greenhouses)

While the Type 4 is efficient, massive greenhouse operations require the brute force of the Type 6. The J624 is frequently employed here to provide lighting electricity and CO2 fertilization on a grand scale.

For facilities covering many hectares, using fewer, larger engines reduces maintenance complexity and logistical overhead compared to a fleet of smaller units, while ensuring the consistent climate control crops need.

To operate these engines profitably, choosing the right fuel is crucial. You can find out more about this in our article:

Maintenance and Rebuilds: Downtime Costs a Fortune

For an IPP, a stationary engine is the worst case. The costs for a day of failure with a 3 MW aggregate are enormous. Therefore, the maintenance strategies for the Jenbacher Type 6 are more aggressive than for small plants.

The general overhaul (rebuild) at 60,000 hours is a major project. Multi-ton components are moved. PowerUP supports here with solutions that save time:

- Exchange Components: We deliver already overhauled cylinder heads or connecting rods, suitable for Jenbacher J620, directly to the construction site.

- Shortblock Exchange: Instead of revising the engine on-site for weeks, we often exchange the core engine (shortblock). This reduces the downtime drastically.

You can read how this process works in detail in our article:

PowerUP: Your Partner for the Heavyweights

Anyone operating a Type 6 needs not just a parts supplier, but a partner with logistics competence. A cylinder head for a J620 is not available at the hardware store.

We at PowerUP have aligned our warehouse and processes with the needs of major customers:

- Availability: We keep critical spare parts (liners, pistons, pre-chamber spark plugs) for Type 6 in stock.

- Independence: We offer alternatives to the often rigid maintenance contracts of the manufacturers.

- Upgrades: We also optimize older J612 or J620 models with modern ignition technology or more durable components to reduce the TCO (Total Cost of Ownership).

Large engines need large service. We are ready.